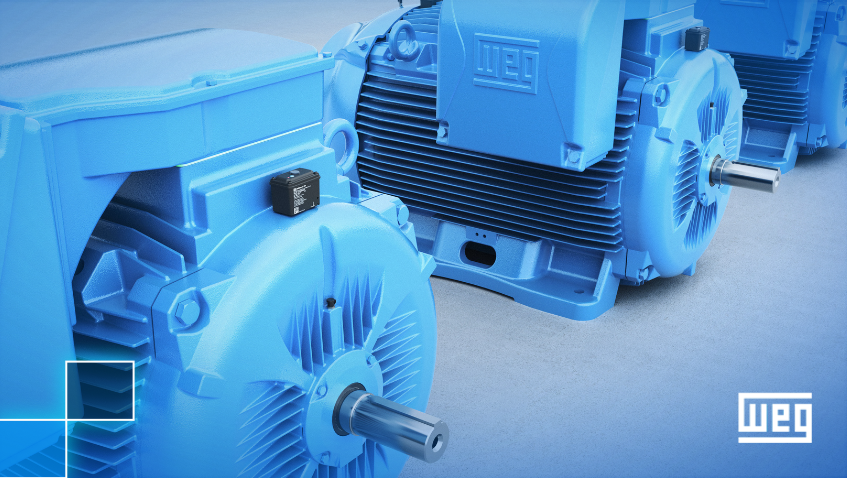

Full Monitoring

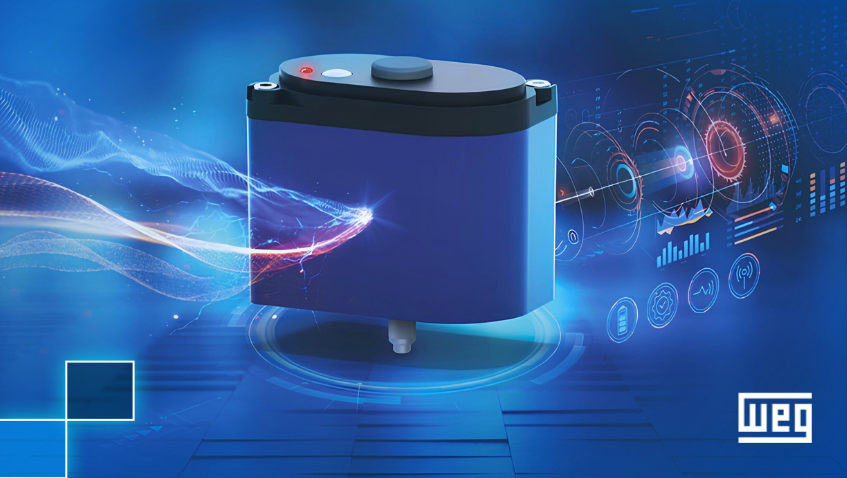

Developed for electric motors and other equipment, after an easy installation, the WEG Motor Scan must be configured through a smart device (App available for Android and iOS). Once configured, the sensor sends data to the cloud via Bluetooth® or Gateway and enables the analysis of the results in WEG Motion Fleet Management, and in greater depth with the WEG Motor Specialist module.

It makes a complete diagnosis of the equipment's operation by measuring temperature, vibration analysis, running time, load, speed, lubrication interval and can operate with alert levels to assist in predictive maintenance.

Artificial intelligence for real results

WEG Motor Scan® learns about the operating patterns and deviations that the monitored electric motor presents during its operation, based on unbalance, misalignment, load and consumption indicators, and makes this data available automatically through the Gateway to the WEG Motor Specialist module in WEG Motion Fleet Management. And it is from this learning that the sensor identifies, without human interference, vibration occurrences that change the operating standards of the monitored equipment. Artificial intelligence in favor of reliability, productivity and machine availability.

With WEG Motor Scan you will be able to

- Connect all the sensors at the plant

- Synchronize data through WEG IoT Platform

- Name and monitor as many motors as you need

- Analyze data sent to the cloud

- Find your motor everywhere

- Get diagnostics

Funcionalities

Motor frame: 63 to 450

Triaxial vibration measurement (up to 3 kHz) in global speed and acceleration values

Vibration spectrum

Unbalance and misalignment diagnosis.

Surface temperature measurement

Estimated load, power, speeds and supply frequency (for motors with direct starter or soft-starter)

Motor running time measurement

Bearing relubrication interval

Battery-powered, estimated service life over 3 years (according to the application);

Ambient temperature: -40 to 80°C

Bluetooth® communication via App and/or Gateway

Dimensions: 44 x 38 x 25 mm

Protection rating: IP66

Direct Starter or Frequency Inverter

Data storage capacity: 3 months

Certifications: Safety/EMC/Radio for the markets: South Africa, Australia, Brazil, Canada, Chile, Colombia, USA, Europe, Malaysia

Product Differentials

Increases equipment efficiency

Maintenance routine optimization

Economy with spare parts replacement

Ready for Industry 4.0

Add value to the product (OEM’s)

Add value to the service (maintenance companies)

Downtime reduction

FAQ

Do you have any doubts about WEG Motor Scan? Check the answers for our Frequently Asked Questions.

The user can register the nameplate data manually through the field “I don't have a serial number”.