Energy efficiency has become a major focus for our government, municipalities as well as power utilities and the industrial sector. Each entity has a specific area where they focus their attention. In every case attention was directed to components, i.e. motors, pumps. I’m sure most everyone is aware of the ESIA Standard (Energy Independence and Security Act) as applied to induction motors.

Efficiency standards as defined by EISA

For each general-purpose rating (Subtype 1) from 1 to 200 horsepower that was previously covered by EPAct, the law specifies a nominal full-load efficiency level based on NEMA Premium efficiency as shown in NEMA MG 1, Table 12-12. All 230 or 460 volt (and 575 volts for Canada) motors currently under EPAct, manufactured after December 19, 2010, must meet or exceed this efficiency level.

General purpose electric motors (Subtype II) not previously covered by EPAct will be required to comply with Energy Efficient efficiencies as defined by NEMA MG 1, Table 12-11. The term general purpose electric motor (Subtype II) means motors incorporating the design elements of a general purpose electric motor (Subtype I) that are configured as one of the following:

· U-Frame Motor

· Design C Motor

· Close-coupled Pump Motor

· Footless Motor Vertical solid shaft normal thrust motor (as in a horizontal configuration)

· An 8-pole motor (900rpm)

· A poly-phase motor with voltage of not more than 600 volts (other than 230 or 460 volts)

· 201 – 500 horsepower motors not previously covered by EPAct will be required to comply with energy efficient efficiencies as defined by NEMA MG I, Table 12-11.

This information as well as the Tables referenced above are readily available on the internet as well as the DOE website. So, what does the new EISA Standard have to do with system efficiency? Most believe that the system efficiency improvement is due to the increase in motor efficiency this is not always the case. Take for example a centrifugal pump system operating at a fixed speed. The system requires variable flow and is controlled by a motor operated valve. One would believe that by replacing the “Standard” Efficiency motor with the new EISA Premium Efficient motor there would be an incremental gain in efficiency and consequently reduced operating cost. Seems like a “no brainer” right? No so fast, there is more to the story.

In order to meet the EISA Standard motor OEM had to redesign their motors in order to achieve the increased efficiency. Let’s define a premium efficient motor. What makes a motor more or for that matter less efficient. Losses in a motor include:

· Stray losses

· Rotor

· Stator

· Core loss

· Fan design (windage)

Motor Losses

To make a motor more efficient, you add more or better material. More active material, copper in the winding and longer stator and rotor cores. Improved electrical steel (silicon steel is used for the stator and rotor). A low loss fan design is used to reduce friction and wind age losses. To reduce the stray load losses, manufacturing processes are assured through ISO9001 procedures.

The advantages of a energy efficient motor?

• Maximum efficiency – Energy efficient motors operate at maximum efficiency even when they are lightly loaded because of their better design.

• Longer life – Energy efficient motors dissipate less heat compared to standard motors, as they are more efficient. Use of energy efficient fans keeps the motor at a lower temperature. This increases the life of the insulation and windings, besides increasing the overall life of the motor.

• Lower operating cost – The total energy cost of energy efficient motors during its life cycle is much lower when compared to conventional motors.

• Other benefits – better tolerance to thermal and electrical stresses, ability to operate at higher temperatures, ability to withstand abnormal operating conditions such as low voltage, high voltage or phase imbalance.

The advantages of energy efficient motors as defined above are accurate. Now let’s look at some other statements that are being made regarding premium efficient motors.

• Utility rebates

• Reduced load

• Energy Savings

Reality check, since the implementation of the EISA Standard most if not all utilities have eliminated the rebate for premium efficient motors. Why? Because it is now mandated by the fendral government. Will the premium efficient motor reduce loading, will it save energy?

After this lengthy explanation on premium efficient (EISA Standard) motors we can get to the main topic of this article System Efficiency.

• Motors meeting higher efficiencies tend to run faster than their less efficient counterparts.

• Matching speeds to applications need (pump flow, fan cfm) is important to consider.

• Drives may be required, which offers the opportunity to increase system efficiency in applications with variable output requirements.

• In some cases, mounting dimensions for motor into machinery may be slightly different.

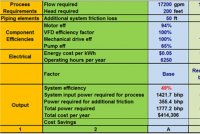

The attached image, is a case study that graphically illustrates the impact of a premium efficient motor in a centrifugal pumping application.

The spread sheet provides four separate scenarios for reducing energy consumption in a Cooling Tower pumping system. The system portrayed is a typical closed loop configuration where the discharge is being throttled over a range of operation. The system in this example operates 24/7, 365 day a year and at this particular load point 70% of the time or 6250 hours per year.

Columns One and Two indicate the various components factored into the system efficiency calculation. Column A is the base condition where the system operates 50% of the time. You will note the component efficiencies for the VFD and gearbox at 100% since they were not utilized. Under the based condition the total power required is approximately 1777hp, almost 356hp is being lost (wasted) across a control valve. In addition the pump is operating back on the curve at 65% efficiency. Under these conditions the total system efficiency is 49%.

Column B provides the new operating conditions with the addition of a variable frequency drive. The head required has been reduced to 150’ since the loss across the valve has been eliminated by reducing the speed of the pump to meet required system demand. Motor efficiency remains the same a 2% loss has been added due to heat generated across the drive. Observe the dramatic improvement in the overall system efficiency (81%) and the total operating cost reduction from $414,306 to $187,360 = cost savings of $226,946 per year.

Column C addresses the impact on the system by improving the efficiency of the pump. Nothing else in the system was changed. Note the minimal improvement of the overall system efficiency (53%) by increasing the pump efficiency 5%. The 50’ head loss across the control valve remains therefore the total power required is 1650hp. Not much of a saving based on the cost of a new pump, installation cost and potential piping changes. Factor in the ongoing reliability issues (pump is still operating back on the curve the $29,593 dollars would be very difficult to justify.

Column D identifies potential savings when motor efficiency is improved by 2%. Again nothing has changed in the system with the exception of an additional Five feet of friction loss across the valve as a result of the reduced slip in the premium efficiency motor (head increases to the square of the speed). In this case the system efficiency remains the same at 49%. Note the power required for the additional friction has increased to 330hp. The total power required was reduced to 1650.2hp (a reduction of 127hp) with a total savings of $518.00 dollars per year.

Conclusion

Premium efficient motors have been mandated by the federal government. The new efficiency standard has many advantages as outlined in this article. When replacing / retrofitting a premium efficient motor one must take into account the impact on the total system. This is especially true in fan and pump applications with variable load requirements under fixed speed conditions.

About the author – William Livoti is the Power Generation Business Development Manager for WEG Electric Corp. Mr. Livoti can be reached at wlivoti@weg.net

References:

• EISA Standards Department of Energy

• WEG Electric