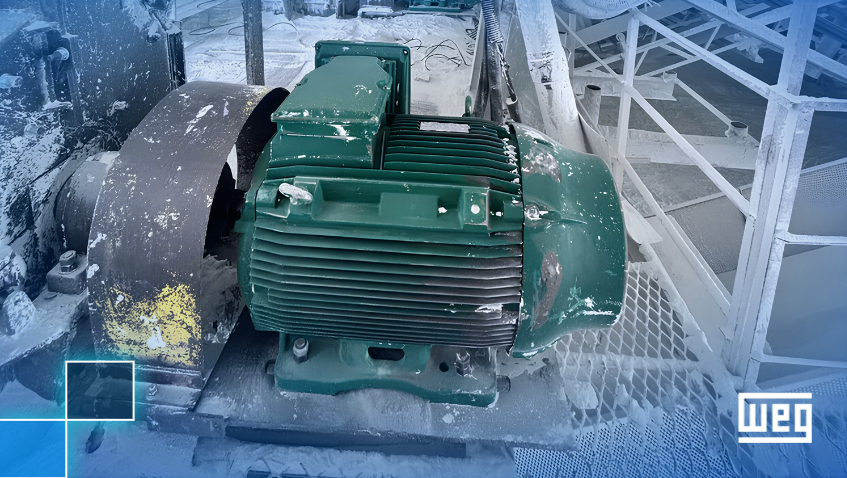

Ball Mills

Flexibility and productivity

Ball Mills are widely used in the ceramic and mining industries, where the grinding process requires strict grain size control.

WEG developed an efficient solution for this application, providing a reduction in electric energy consumption of up to 35%. The solution consists of a high-efficiency set: W22 Magnet IE4 Super Premium or W22 Magnet IE5 Ultra Premium motor driven by the CFW11 variable speed drive.

The motor speed control can be adjusted so as to optimize the grinding process, allowing greater contact between the balls as the material grain is reduced to the desired size.

Through this resource, the gains go beyond energy savings, including greater productivity with a shorter grinding cycle, operating flexibility with the same mill being able to process different materials and lower mechanical wear of the equipment.

Benefits

- Savings of up to 35% and increased production.

- Greater productivity due to shorter grinding time.

- Greater operating flexibility due to adjustments of the grinding cycles according to the kind of product or raw material.

- Reduced mechanical wear of the mill (internal walls and balls).