Operaciones circulares y eficientes

La economía circular busca maximizar el valor de los recursos mientras minimiza el desperdicio y los impactos ambientales. En este modelo, los productos son proyectados para ser durables, reparables y reciclables, incentivando la reutilización y el reciclaje de materiales. En vez de seguir el tradicional modelo lineal de producción y consumo, en que los productos son fabricados, usados y descartados, la economía circular promueve la idea de un ciclo continuo, donde los materiales son mantenidos en uso por el mayor tiempo posible.

Ese abordaje no solamente contribuye a la conservación de los recursos naturales, sino que también estimula la innovación, la creación de empleos y el crecimiento económico sustentable, tornándose esencial para enfrentar los desafíos globales de hoy, como los cambios climáticos y la escasez de recursos.

Consolidando el compromiso WEG, poseemos certificaciones ISO 14.001 demostrando la gestión ambiental en las operaciones de la empresa.

Programas & Prácticas

Residuos y energía

Residuos Sólidos

WEG tiene un sistema de recolección selectiva de residuos en sus operaciones. De esa forma, los residuos son separados y enviados a los recicladores de cada uno de los materiales, posibilitando así su valorización y la reintroducción de los materiales en los más diversos ciclos productivos. Es importante enfatizar que parte de los residuos generados en las operaciones son reciclados por la propia WEG, retornando así al proceso y haciendo parte de sus productos. Todos los residuos son enviados a empresas ambientalmente responsables, seleccionadas y desarrolladas por el equipo de gestión ambiental de WEG.

Energía

WEG cuenta con la Política de Eficiencia Energética, desde 2012, en la cual demuestra su compromiso con la gestión de ese insumo. Esa política es desdoblada en acciones para el monitoreo y la reducción del consumo de energía, lo que contribuye a la mejora del medio ambiente. WEG pretende tornar, cada vez más, sus fuentes de energía más limpias, renovables y sustentables.

Agua, efluentes y recursos hídricos

WEG monitorea el consumo de agua de sus operaciones y tiene diversos controles operacionales que garantizan una gestión eficiente sobre ese recurso, evitando así el desperdicio y promoviendo un consumo consciente. Todos los efluentes generados en las operaciones son debidamente tratados y periódicamente monitoreados, de forma de garantizar el cumplimiento de las legislaciones y la minimización de los impactos en los diferentes stakeholders.

Parte de los efluentes tratados en las operaciones son reutilizados en los procesos internos, donde algunas estaciones de tratamiento de efluentes posibilitan hasta 100% de reúso del efluente tratado. Adoptamos iniciativas focalizadas en la reducción del consumo de agua y de la generación de efluentes, a través del control de pérdidas, del monitoreo del consumo y del apoyo a los programas que involucran a todos los colaboradores a ese objetivo, como el KaizenWEG y el WEG Manufacturing System.

Inversiones y gastos en medio ambiente

Las inversiones ambientales son caracterizadas en tres categorías:

- Control ambiental: relacionado con el tratamiento y la disposición de residuos, tratamiento de emisiones atmosféricas y líquidas, seguros de responsabilidad ambiental y depreciación de equipos y gastos con materiales y servicios de mantenimiento.

- Equipos: relacionados a la adquisición de equipos para control ambiental.

- Gestión: relacionado a la remuneración de profesionales de capacitación que ejercen actividades de gestión ambiental, investigación y desarrollo, y a la certificación de sistemas de gestión ambiental.

Embalajes sustentables y preservación de la biodiversidad

Poseemos una fábrica de embalajes, RF Reflorestadora, localizada en Brasil. Esa unidad produce todos los embalajes de madera utilizados en nuestras diversas líneas de producto. Para eso, contamos con áreas de reforestación propias que garantizan el suministro continuo de madera y la preservación de ese recurso natural y de áreas de bosques naturales, reserva legal y áreas de preservación permanente que ayudan en la conservación de la biodiversidad local.

Las áreas cumplen todas las legislaciones y requisitos legales, así como un área de conservación de bosques nativos muy superior al mínimo de la reserva legal establecida.

Además de eso, WEG promueve y apoya iniciativas de reforestación consciente y conservación de la naturaleza, e invierte en la arborización de sus parques fabriles.

KaizenWEG

KaizenWEG fue creado en 2016 y es el corazón del sistema de gestión de mejora continua de WEG, el WMS, donde todos los colaboradores son incentivados a promover mejoras en su entorno de trabajo o en cualquier otra área de la empresa, identificando desperdicios, analizando causas y participando en equipos multidisciplinarios para la resolución de problemas.

Siendo uno de los pilares de la Gestión Participativa de la Compañía, desde su creación se han implementado más de 300 mil mejoras, aportando mayor seguridad, calidad y productividad, además de hacer el entorno laboral cada vez más eficiente y sostenible.

La búsqueda colectiva de la excelencia operativa y la sostenibilidad en un escenario de verticalización de procesos convierte a la gestión participativa en una pieza clave para potenciar los resultados de WEG.

Mira el video del lanzamiento de la nueva plataforma de KaizenWEG:

WMS (WEG Management System)

El sistema de gestión de mejora continua de WEG es el WMS, que tiene como principal objetivo la identificación y eliminación de pérdidas y desperdicios.

Los resultados son maximizados a través de las matrices de priorización de seguridad, calidad, costo y emisiones de GEE (gases de efecto invernadero horno), que direccionan la implementación de proyectos de optimización o eliminación de estos desperdicios, contribuyendo a un mundo más eficiente y sustentable.

Además de los frentes de trabajo de optimización, equipos multidisciplinarios actúan como puntos focales de mejora continua, trayendo innovaciones y disrupciones a nuestros procesos.

Uno de estos puntos de foco es el pilar de Medio Ambiente y Energía, que focaliza y sistematiza la reducción de impactos ambientales, actuando para reducir o eliminar la generación de residuos y emisiones, el consumo de recursos energéticos, limpiezas químicas e insumos en general.

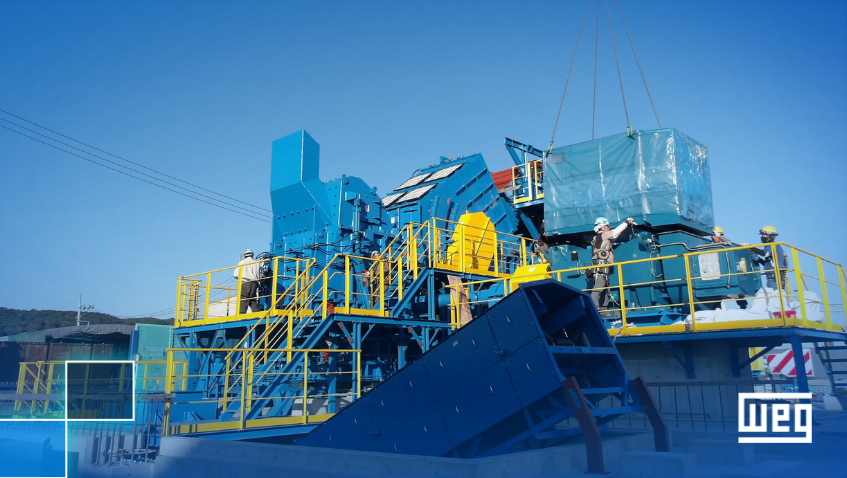

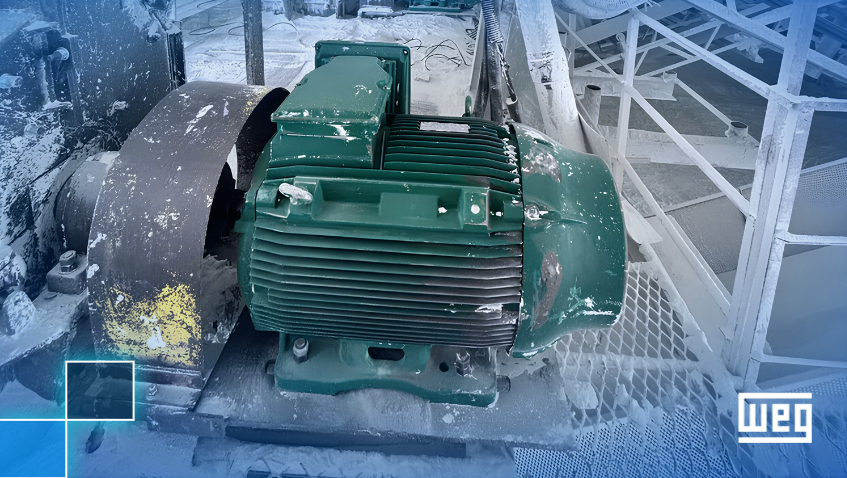

Plan de Intercambio WEG (Disponible solo en Brasil)

El reciclaje es un tema serio para WEG, extendiéndose incluso a su negocio. Mediante el programa de reutilización de motores eléctricos, el "Plan de Intercambio", la empresa otorga un descuento en la compra de un nuevo motor con un rendimiento superior a los requisitos legales a cambio de uno usado. Además del beneficio financiero para los clientes, la iniciativa garantiza que el motor de baja eficiencia ya no se utilice. Una vez recogidos por la empresa, los motores se desmantelan y se separan en piezas para ser distribuidos a recicladores acreditados y rastreados.

Beneficios

Reducción del consumo de energía eléctrica

Confiabilidad de la planta

Reducción de costos operativos

Garantía de fábrica

Productos normalizados: ofrecen total intercambiabilidad con motores ya instalados

Item | 2021 | 2022 | 2023 | 2024 |

Productos vendidos que pueden ser reutilizados o reciclados* (%) - Base en peso | 68 | 73 | 65 | 70 |

Productos que fueron realmente reaprovechados o reciclados por la empresa* (%) - Base en peso | 12 | 16 | 14 | 4 |

*Porcentaje basado en el peso de los productos vendidos en el año.

Inversiones en Medio Ambiente

Las inversiones ambientales se clasifican en dos categorías:

Inversiones de capital: Se refieren a la adquisición de equipos de control ambiental.

Gastos operativos (R$): Se refieren al tratamiento y disposición de residuos, el tratamiento de emisiones atmosféricas y líquidas, el seguro de responsabilidad ambiental y la depreciación de equipos, así como a los gastos de materiales y mantenimiento, y a los gastos de remuneración del personal que trabaja en gestión ambiental, investigación y desarrollo, y certificación de sistemas de gestión ambiental.

A continuación, se detalla el monto invertido en cada categoría:

Item | 2021 | 2022 | 2023 | 2024 |

Inversión de capital (R$) | 1.329.000 | 1.788.000 | 1.819.000 | 11.141.393 |

Gastos operativos (R$) | 14.684.000 | 17.753.000 | 23.509.000 | 33.605.910 |

| % de cobertura (%) | 70 | 70 | 70 | 89 |

Certificación Ambiental

En 2024, considerando el alcance de los empleados, el 70,8% del grupo WEG estaba cubierto por la certificación ISO 14001.

Haga clic aquí para acceder a los certificados

Auditorías ambientales

WEG cuenta con un proceso de auditoría ambiental que abarca todas sus operaciones industriales.

En el proceso de auditoría ambiental anual, WEG garantiza el cumplimiento de la legislación ambiental en todas sus operaciones industriales.

Indicadores de Rendimiento

En 2023, se amplió el alcance de las unidades monitorizadas, incluyendo las direcciones comerciales de la empresa. Así, ahora el 100 % de las direcciones globales de WEG están incluidas en los indicadores.

Energía

WEG tiene una política de eficiencia energética desde 2012, en la que muestra su compromiso con la gestión de este recurso. Esta política desarrolla acciones para monitorear y reducir el consumo de energía, lo que contribuye a mejorar el medio ambiente. WEG tiene la intención de hacer cada vez más limpias, renovables y sostenibles sus fuentes de energía.

Consumo Total de Energía | Unidad | 2019 | 2020 | 2021 | 2022 | 2023 |

Consumo total de energía no renovable | MWh | 466,737 | 462,976 | 499,355 | 478,872 | 430,848 |

Consumo total de energía renovable | MWh | 0 | 0 | 56,000 | 86,918 | 127,709 |

Consumo total de energía (no renovable + renovable) | MWh | 466,737 | 462,976 | 555,355 | 565,790 | 558,557 |

Cobertura de datos (% del denominador) | porcentaje de empleados | 100 | 100 | 100 | 100 | 100 |

Adquisición de energía renovable

En 2023, WEG garantizó que el 22,9% del consumo de energía procediera de fuentes renovables con garantía de origen mediante autoproducción, compra de certificados de energía renovable (I-REC) y contratos bilaterales.

En 2024, WEG tendrá aproximadamente el 90% del consumo de electricidad de Brasil proveniente de fuentes renovables, lo que equivale a un promedio de 45 MW.

Emisiones atmosféricas

WEG monitorea las emisiones atmosféricas relacionadas con compuestos orgánicos volátiles. A continuación se muestra el resultado de las emisiones relacionadas con equipos monitoreados en los últimos años.

Item | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 |

Emisiones de compuestos orgánicos volátiles (COV) (toneladas/año) | 93,5 | 135,2 | 114,5 | 139,3 | 191,3 | 241,3 |

Tasa de cobertura (%) | 56 | 56 | 56 | 61 | 72 | 61 |

Infracciones ambientales

Una de las principales prioridades de WEG es cumplir con la legislación ambiental aplicable a sus operaciones. En los últimos 4 años, no hubo evidencia de multas ambientales significativas aplicadas a las actividades de WEG.