Motores e Redutores

Eficiência e confiabilidade para a indústria de alimentos e bebidas

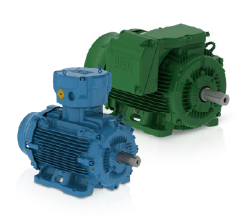

A fabricação dos motores elétricos WEG começou com as habilidades combinadas de um eletricista, um administrador e um mecânico, o que resultou na produção do primeiro motor elétrico WEG. Desde então, é isso que nos guia para produzir máquinas mais eficientes, projetadas com as mais avançadas tecnologias. Tudo isso porque, independentemente do segmento de mercado, a WEG mantém dedicadas iniciativas de pesquisa e inovação para produzir motores elétricos de alta eficiência, que garantem a confiabilidade da produção para sua indústria.

A WEG oferece diversas soluções com motores elétricos e redutores, como motores de ímãs permanentes, pintura antimicrobiótica e resistente à corrosão e novas tecnologias para a Indústria 4.0, como o WEGScan®. São produtos especificamente projetados para qualquer aplicação na Indústria de Alimentos e Bebidas.

Preparação, processo e sistemas HVAC

Esses sistemas incorporam diversas soluções WEG, como motores para ventilação em diferentes indústrias de alimentos e bebidas. Além disso, a WEG oferece o W30 Smart EC (WEG Electric Commutated Motor), projetado para túneisde congelamento, condensadores e evaporadores; o W12, que pode ser usado com redutores, bombas e ventiladores, enquanto a linha W22 oferece toda a sua versatilidade e eficiência. Desenvolvidos para grandes sistemas de exaustão e bombeamento, os motores W60 oferecem altos níveis de eficiência energética, ideais para aplicações de alta velocidade.

Ambientes de aplicação de lavagem

Aplicações que exigem processo de lavagem contínua (manuseio de proteína animal, como: carne suína, bovina, ovina e aves) exigem equipamentos seguros. A WEG oferece soluções como os Motores Washdown Encapsulados Hydroduty e Picker Plus, e Motores Washdown de Uso Geral Hydrowash, Shark e W22 Wash, que apresentam NobaC®, pintura exclusiva da WEG com propriedades antimicrobianas.

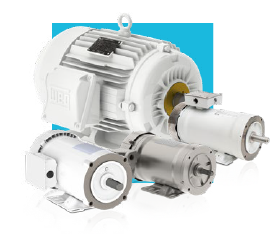

Pequenas máquinas e food service

A WEG oferece uma gama diversificada de motores comerciais, projetados especificamente para pequenas máquinas em áreas secas. Essas soluções são versáteis e adequadas para várias indústrias ou equipamentos usados no setor de food service.

Refrigeração industrial e compressores de ar

Na área de utilidades, aplicações como amônia e compressores de ar exigem produtos dedicados e confiáveis.

A WEG também oferece a linha W60, com design compacto e fluxo de ar otimizado, dedicada a bombas, ventiladores, compressores, moinhos e outros. O destaque é a linha de motores W22 Cooling Tower, utilizados em torres de resfriamento.

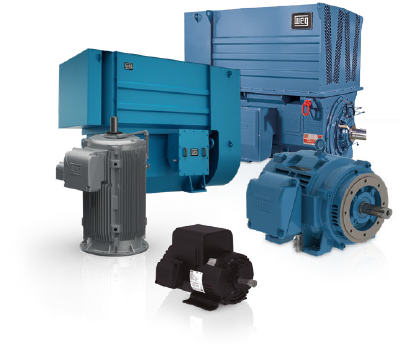

Aplicações pesadas

Motorredutores como WG20, Magmax, MAS e GSA, combinados com a linha de motores W22 e W12, são adequados para aplicações como transportadores, máquinas de laminação, agitadores, guinchos, elevadores, picadores e outros. Algumas aplicações podem receber pintura antimicrobiana especial, resistente à corrosão, o que é importante para a indústria de alimentos e bebidas.

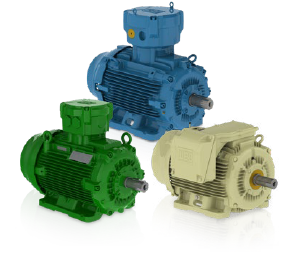

Áreas de risco

Esses motores elétricos atendem às necessidades de áreas de risco, pois são fabricados de acordo com as normas industriais vigentes, tanto NEMA quanto IEC. Os produtos são certificados pelos principais órgãos de certificação de produtos do mundo, além de terem altos níveis de segurança, essenciais para Zona 1 (linha W22Xdb), Zona 2 (W22Xec) e Zona 21/22 (W22Xtb). Com uma construção robusta, são os mais modernos acionamentos para máquinas de áreas de risco que contenham gás, vapor ou poeira.

WEGSee+

O WEGSee+ é um software gratuito e multiplataforma que simula a aplicação de motores elétricos de alta eficiência para reduzir o consumo de energia na indústria. Ele gera relatórios de viabilidade para substituição de motores elétricos, calculando o potencial de economia em termos financeiros e energéticos. O software também apresenta indicadores financeiros, como VPL e TIR, e permite que você simule a capitalização de recursos por meio de diferentes formas de investimento.

Motores WEG para áreas industriais de Alimentos e Bebidas

A indústria de alimentos e bebidas abrange várias zonas higiênicas, cada uma exigindo considerações específicas para mitigar o risco de contaminação de alimentos. Entender o motor ideal para sua aplicação nessas áreas industriais é essencial, levando em consideração especificações técnicas, fatores de sustentabilidade e requisitos de saneamento. Encontrar um único fornecedor capaz de abordar todos esses aspectos pode ser um desafio significativo, mas não se preocupe, a WEG é especializada em soluções personalizadas para a indústria de alimentos e bebidas e está preparada para ajudá-lo a identificar sua zona de segurança alimentar e selecionar os produtos mais adequados.

A WEG oferece uma gama abrangente de motores adequados para instalações externas e internas. No entanto, antes de explorar nossas ofertas de produtos para essas aplicações, é crucial verificar sua zona de segurança alimentar (1-4). Ao fazer parceria com a WEG, você pode acessar a expertise e as soluções projetadas para otimizar a higiene, o desempenho e a confiabilidade em seu ambiente industrial específico.

|

Zona 4 |

Áreas fora das áreas de processamento de alimentos |

|

Zona 3 |

Superfícies sem contato com alimentos (área seca) |

|

Zona 2 |

Superfícies sem contato com alimentos (área molhada) |

|

Zona 1 |

Superfícies de contato com alimentos |

Agora que sabemos sobre as diferentes zonas de segurança alimentar, você pode escolher com confiança o motor que melhor se adapta às suas necessidades. Seja para sistemas de transporte, máquinas de embalagem/dosagem ou aplicações de transferência de líquidos, a WEG oferece um abrangente portfólio de motores que atende a todos os requisitos e padrões da indústria de alimentos e bebidas.

Motores Washdown

Aplicações que exigem processo de lavagem contínua (manuseio de proteína animal, como: carne de porco, carne bovina, cordeiro e aves) exigem equipamentos seguros. A WEG oferece soluções como os Motores Washdown Encapsulados Hydroduty e PickerPlus, e Motores Washdown de Uso Geral Hydrowash, Shark e W22 Wash, que apresentam NobaC®, pintura exclusiva da WEG com propriedades antimicrobianas. Esses tipos de motores são perfeitos para instalação nas zonas 1 e 2, e seguem a construção segura para alimentos (sem folgas).

Shark

Para uso em processamento de alimentos, aplicações farmacêuticas e outras que exigem extrema limpeza.

| ESCOPO DO PRODUTO | |

| Potência | 1 – 30 HP |

| RPM | 1.800 e 3.600 |

| Tensão | 230/ 460 V (60 Hz) |

| Resfriamento | TFVE, TFSV |

| Carcaça | 143TC a 286TC |

| Montagem | Flange C sem pé ou Flange C com pé |

Hydro Duty

O melhor motor washdown de aço inoxidável da indústria. Reduz significativamente os custos de substituição e tempo de inatividade do motor.

| ESCOPO DO PRODUTO | |

| Potência | 0,5 – 30 HP |

| RPM | 3.800, 1.800, 1.200 e 900 |

| Tensão | 208-230/ 460 V @ (60 Hz) / De-rated @ 50Hz |

| Resfriamento | TFVE, TFSV |

| Carcaça | 56C até 210C (100 e 80 IEC disponíveis) |

| Isolamento | Classe F, apto a inversor, atendendo à NEMA MG 1 Part 31 |

| Montagem | Flange C sem pé ou Flange C com pé |

HydroWash

Projetado para longa vida útil em aplicações de lavagem de uso geral.

| ESCOPO DO PRODUTO | |

| Potência | 0,5 – 25 HP |

| RPM | 3.600, 1.800 e 1.200 |

| Tensão | 208-230/ 460 V e 575 V opcional |

| Resfriamento | TFVE (TFSV disponível nos motores fracionários (60/50 Hz)) |

| Carcaça | 56C – 250TC |

| Isolamento | Classe F, apto a inversor, atendendo à NEMA MG 1 Part 31 |

| Montagem | Flange C sem pé ou Flange C com pé |

PickerPlus

Bobinado encapsulado e um sistema de vedação patenteado para garantir que eles “resistirão” nas aplicações mais severas.

| ESCOPO DO PRODUTO | |

| Potência | 3 HP |

| RPM | 1.800 |

| Tensão | 230/ 460 V (60 Hz) |

| Resfriamento | TFVE |

| Carcaça | 100L ou 145TC |

| Montagem | Flange C ou Flange C com pé |

Caraterísticas | HYDRODUTY | PICKERPLUS | HYDROWASH | SHARK MOTORS |

Bobina encapsulada | X | X |

|

|

Carcaça de aço inoxidável 304 | X |

|

| X |

Defletora de aço inoxidável 304 | X | X |

| X |

Respiradouro de ar | X | X | X |

|

Conexão EZ (56/140T) | X |

|

|

|

Passagem de cabos encapsulados |

| X | X |

|

Passagem de cabos com junta de vedação |

|

|

| X |

Anel O'ring na junta de proteção tampa/carcaça | X | X |

| X |

Selante para junta de proteção tampa/carcaça |

|

| X |

|

Pintura em pó branca epóxi |

| X | X |

|

Anel de proteção do eixo de aço inoxidável | X | X | X | X |

Eixo de aço inox | X | X | X | X |

Grau de proteção | IP69K | IP69K | IP56 | IP56 |

Saiba mais sobre nossas soluções

Faça o download do nosso catálogo e conheça mais sobre nossas soluções para o segmento de alimentos e bebidas.

Download