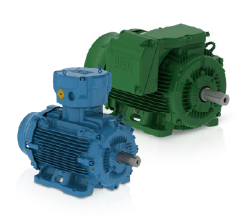

Motors and Gearboxes

The manufacture of WEG electric motors started with the combined skills of an electrician, an administrator and a mechanic, which resulted in the production of the first WEG electric motor. Since then, that is what guides us to produce more efficient machines, designed with the most advanced technologies. All that because, regardless of the market segment, WEG keeps dedicated research and innovation initiatives to produce highly efficient electric motors, which guarantee the production reliability for your industry.

WEG offers various solutions with electric motors and gearboxes, such as permanent magnet motors, antimicrobiotic and corrosion resistant painting, and new technologies for Industry 4.0, such as WEGScan®. These are products specifically designed for any application in the Food and Beverage Industry.

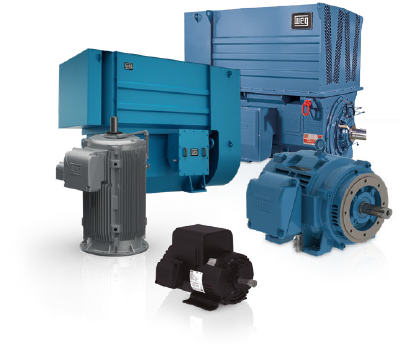

Preparation, process and HVAC systems

These systems incorporate several WEG solutions, such as motors for ventilation in differente Food an Beverage industries. Additionaly, WEG offers the W30 Smart EC (WEG Electric Commutated Motor), which is designed for freezing tunnels, condensers and evaporators; the W12 which can be used with gearboxes, pumps and fans, while the W22 line offers all of its versatility and efficiency. Developed for large exhaust and pumping systems, the W60 motors offer high levels of energy efficiency, ideal for high speed applications.

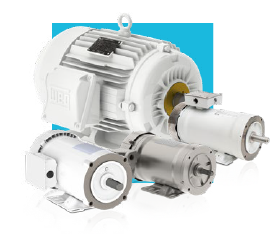

Washdown application environments

Applications requiring continuous washdown process (handling animal protein, such as: pork, beef, lamb and poultry) demand safe equipment. WEG offers solutions like the Encapsulated Washdown Motors Hydroduty and Picker Plus, and General Purpose Washdown Motors Hydrowash, Shark and W22 Wash, which features NobaC®, exclusive WEG paiting with antimicrobial properties.

Small machines and food service

WEG offers a diverse range of commercial motors, specifically designed for small machines in dry area. These solutions are versatile and suitable for various industries or equipment used in food service.

Industrial refrigeration and air compressors

In utilities area, applications such as ammonia and air compressors demand dedicated and realiable products.

WEG also offer the W60 line, with a compact design and optimized air flow, dedicated to pumps, fans, compressors, mills, and others. The highlight is the W22 Cooling Tower motor line, used in cooling towers.

Heavy applications

Gearmotors such as the WG20, Magmax, MAS and GSA, combined with W22 and W12 motor line, are suitable for applications like conveyors, rolling machines, stirrers, winches, elevators, chippers and others. Some applications may receive special antimicrobial painting, resistant to corrosion, which is important for the Food and Beverage industry.

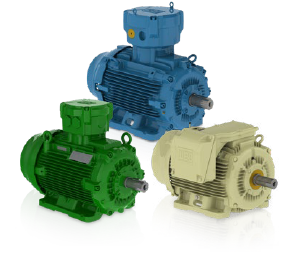

Hazardous locations

These electric motors meet the needs of hazardous locations, as they are manufactured according to current industrial standards, both NEMA and IEC. The products are certified by the main product certification bodies in the world, in addition to having high safety levels, essential for Zone 1 (W22Xdb line), Zone 2 (W22Xec) and Zone 21/22 (W22Xtb). With a robust construction, they are the most modern drives for hazardous locations machines containing gas, steam or dust.

WEGSee+

WEGSee+ is a free, multiplatform software that simulates the application of high-efficiency electric motors to reduce energy consumption in industry. It generates feasibility reports for replacing electric motors, calculating the potential savings in financial and energy terms. The software also presents financial indicators, such as NPV and IRR, and allows you to simulate the capitalization of resources through different forms of investment.

WEG motors for Food and Beverage industrial areas

The food and beverage industry encompasses various hygienic zones, each requiring specific considerations to mitigate the risk of food contamination. Understanding the optimal motor for your application within these industrial areas is essential, taking into account technical specifications, sustainability factors, and sanitation requirements. Finding a single supplier capable of addressing all these aspects can be a significant challenge, but don’t worry, WEG specializes in solutions tailored for the food and beverage industry and is poised to assist you in identifying your food safety zone and selecting the most suitable products.

WEG offers a comprehensive range of motors suitable for both outdoor and indoor installations. However, before exploring our product offerings for these applications, it is crucial to ascertain your food safety zone (1-4). By partnering with WEG, you can access expertise and solutions designed to optimize hygiene, performance, and reliability in your specific industrial environment.

Zone 4 | Areas outside food processing areas |

Zone 3 | Non-food contact surfaces (dry area) |

Zone 2 | Non-food contact surfaces (wet area) |

Zone 1 | Food contact surfaces |

Now we know about the different food safety zones, you can confidently choose the motor that best suits your needs. Whether it’s for conveyor systems, packing/dosing machines, or liquid transfer applications, WEG offers a comprehensive motor portfolio that meets all the requirements and standards of the food and beverage industry.

Washdown motors

Applications requiring continuous washdown process (handling animal protein, such as: pork, beef, lamb and poultry) demand safe equipment. WEG offers solutions like the Encapsulated Washdown Motors Hydroduty and Picker Plus, and General Purpose Washdown Motors Hydrowash, Shark and W22 Wash, which features NobaC®, exclusive WEG paiting with antimicrobial properties. These kinds of motors are a perfect fit to installation at zone 1 and 2, and follow the food safe construction (no gaps).

Shark

For use in food processing, pharmaceutical and other applications requiring extreme cleanliness.

| PRODUCT SCOPE | |

| Horsepower | 1 – 30 HP |

| RPM | 1.800 and 3.600 |

| Voltage | 230/ 460 V (60 Hz) |

| Enclosure | TEFC, TENV |

| Frames | 143TC to 286TC |

| Mounting | C-Face footless or C-Face Footed |

Hydro Duty

best stainless washdown motor in the industry.Significantly reduces motor replacement and downtime costs.

| PRODUCT SCOPE | |

| Horsepower | 0.5 to 10 HP |

| RPM | 3,800, 1,800, 1,200 and 900 |

| Voltage | 208-230/460 V @ 60 Hz / De-rated HP @ 50 Hz |

| Enclosure | TENV and TEFC |

| Frames | 56C through 210TC (100 and 80 IEC frames available) |

| Insulation | Class-F inverter rated, meeting NEMA MG 1 Part 31 |

| Mounting | C-Face footless or C-Face Footed |

HydroWash

Designed for long service life in general purpose washdown applications.

| PRODUCT SCOPE | |

| Horsepower | 0.5 to 25 HP |

| RPM | 3.600, 1.800 and 1.200 |

| Voltage | 208-230/460 V and 575 V as optional |

| Enclosure | TEFC (TENV available for fractional motors (60/50 Hz)) |

| Frames | 56C – 250TC |

| Insulation | Class-F inverter rated, meeting NEMA MG 1 Part 31 |

| Mounting | C-Face footless or C-Face Footed |

PickerPlus

Encapsulated winding and a patented sealing system to ensure they will “standup” in the most severe applications.

| PRODUCT SCOPE | |

| Horsepower | 3 HP |

| RPM | 1.800 |

| Voltage | 230/ 460 V (60 Hz) |

| Enclosure | TEFC |

| Frames | 100L or 145TC |

| Mounting | C-Face footless or C-Face footed |

Features | HYDRODUTY | PICKERPLUS | HYDROWASH | SHARK MOTORS |

Encapsulated winding | X | X |

|

|

304 Stainless steel frame | X |

|

| X |

304 Stainless steel fan cover | X | X |

| X |

Breather vent | X | X | X |

|

EZ-Connect (56/140T) | X |

|

|

|

Potted leads passage |

| X | X |

|

Gasketed leads passage |

|

|

| X |

O'ring on end shield/shell joint | X | X |

| X |

End shield/shell joint sealant |

|

| X |

|

White powder epoxy coating |

| X | X |

|

Stainless steel shaft slinger | X | X | X | X |

Stainless steel shaft | X | X | X | X |

IP degree | IP69K | IP69K | IP56 | IP56 |

Know more about our solutions

Download our brochure and know more about our solutions for Food and Beverage.

Download