Growing population and rapid development around the Municipality and Johannesburg are some of the challenges faced by the Department of Water and Sanitation in South Africa. The over utilized capacity of Sebokeng Wastewater Treatment Works, part of Sedibeng Regional Sewer Scheme, had its capacity increased from 100Ml/d to 150Ml/d with the addition of Module Six (6).

This scenario identified the drivers for improvements and upgrading; and presented new opportunities for WEG as a manufacturer of electrical solutions.

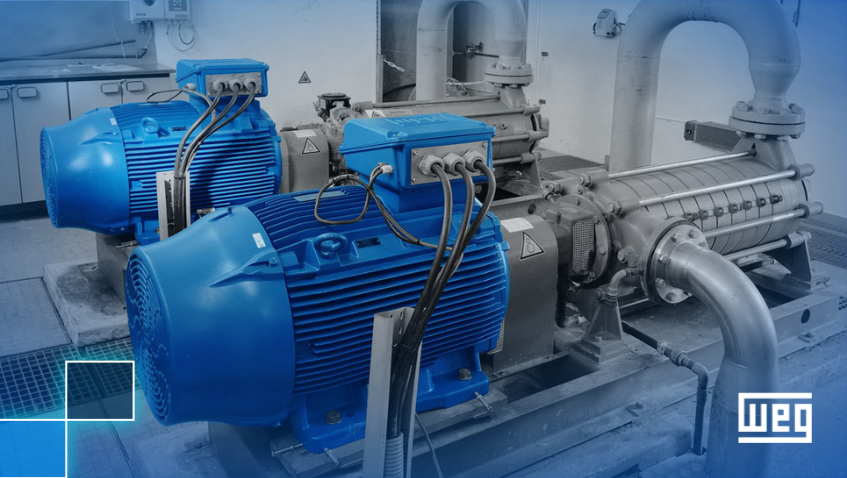

Zest WEG’s team of specialists in partnership with PCI Africa, one of Africa's leading purification systems designers and contractors of water and waste water solutions for the municipal and industrial markets, joined skills and supplied many solutions for the entire wastewater treatment works. WEG motors are installed in all major processes, from screening, sand removal, primary sedimentation, reactors, fermentation of raw sludge, final clarification, waste sludge thickening up to dewatering.

After many years of unforeseen delays Module Six (6) portion at Sebokeng – Emfuleni has finally been commissioned.

PROJECT DESCRIPTION

The project is located approximately 50 km south of Johannesburg, in South Africa, and involved the demolition of existing water tanks, earth-moving operations, excavation for terracing purposes, and concrete works for the rehabilitation of the Sebokeng wastewater treatment plant – Module 6, leading to an overall capacity of 150 Ml/day.

The scope of supply included several low voltage W22 electric motor solutions ranging between 3kW and 280kW, suitable for applications all over the entire WWTW works consisting of the following:

Mechanical Plant

• 2 off 50Ml/day screw pumps fitted with 280kW motors.

• 4 off front rake screens and hydro conveyors.

• 2 off compactors.

• 2 off 30m PST half bridges with 2 recycle pumps per tank.

• Bioreactor consisting of 1 mixer and 21 aerators varying from 30kW to 90kW.

• 6 off A recycle pumps and 4 off R recycle pumps.

• 3 off 30m half bridge SST’s each with 2 off RAS pumps.

• 2 off WAS pumps feeding to the dewatering holding tanks.

• Chlorine dosing system for dosing from 1-ton drums c/w dosing pumps.

Sludge Treatment Process

• 2 off sludge holding tanks with floating aerators.

• 6 off turbo drain presses feeding into 6 off dewatering presses.

• All the necessary pumps and associated equipment.

This project reinforces WEG capacity of supplying innovative and quality products to the Water Segment, and confirms that the company is in line with customers’ needs by improving energy efficiency, reliability of plant operation performance and reducing the environmental footprint. Also, the involvement of Zest WEG local branch expertise was critical for the good relationship with the integrator’s team.