Pumping Systems

Used in different segments, it may present savings of up to 70% in energy consumption when WEG solution is employed. In addition to reducing water consumption and cutting down costs with maintenance and operation of the system flow and control valves.

Know moreExhaust Ventilation System

Used in different segments, it may present savings of up to 70% in energy consumption when WEG solution is employed. In addition to cutting down costs with maintenance and operation of dampers and improving the system flow control. In combustion fans, the quality of the burn may be improved and fuel consumption may be reduced.

SAIBA MAISCooling Tower

Water cooling system commonly used in the industry, whether for cooling air conditioning systems or equipment. Electric energy savings obtained with WEG solution for this application range from 40 to 80%, besides saving water and chemicals.

Know moreBag Filter

Air filtering equipment is widely used in the industry, whether for work station cleaning and dedusting or gas exhaustion. Learn how WEG solution can reduce energy consumption of your bag filter in up to 60%. In addition to other advantages, such as extended life of the filtering element, lower compressed air consumption and reduced piping wear.

Know moreConforto Animal

A aplicação acoplada diretamente ao ventilador pode apresentar uma economia de energia de até 45%, aliando redução de custos e assegurando maior produtividade através da manutenção do fluxo do ar e menor nível de ruído, além da redução nas emissões de CO2.

SAIBA MAISGrain Storage Silos

One of the most important applications in agribusiness designed to store and keep the grain quality. WEG solution allows reducing electric energy consumption in up 90%. In addition to gains such as precise volume control of the stored product and improvement of the grain quality.

Know moreExtruder

Machine used in a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. WEG solution may produce energy savings of up to 30% in such application.

Know moreHydraulic Power Units

Hydraulic units are composed of different devices, from displacement pumps, directional valves and retention valves to oil tanks. WEG solution exclusively designed for this system allows reducing electric energy consumption in up to 60%.

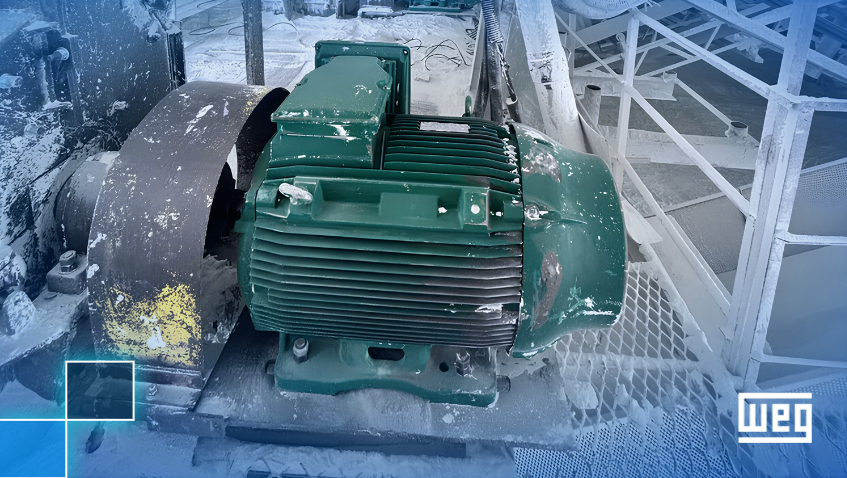

Know moreBall Mill

Widely used in grain size control in the ceramic and mining industry. WEG solution may reduce consumption in up to 35%. In addition to productivity enhancement, operational flexibility and reduced mechanical wear of the equipment.

Know moreAir Compressor

Machines that greatly benefit from energy efficiency projects. Electric energy consumption may reduce up to 30% with greater pressure uniformity in the line and lower mechanical wear.

Know moreRefrigeration Compressor

Machines that present high energy consumption in meat packing plants, supermarkets, shopping malls, among other businesses that use cold rooms. The reduction in the energy consumption may reach 30% when WEG solution is employed. Other gains include temperature uniformity in the cold room, greater thermal comfort and reduced mechanical wear.

Know moreSolução Redutores

Você sabia que os redutores de velocidade podem proporcionar até 60% de economia de energia?

Know more