Selected products were added to comparison

See products on comparison page

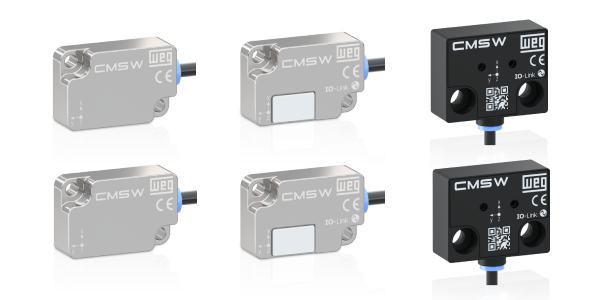

Representative Image Only

CMSW condition monitoring sensors are an intelligent and efficient solution in asset monitoring.Aimed at those seeking to avoid unexpected machines and processes, reduce maintenance costs and improve operational efficiency of machines.These sensors offer real -time information about machine and equipment operating variables in general.They are able to continually monitor up to four different working condition variables, such as: vibration, contact temperature, humidity and atmospheric pressure.Are available in Modbus and IO-Link.

Description

The CMSW range is developed with excellent quality and technology in order to improve machine performance. These devices are capable of continuously monitoring up to six different machine and equipment working condition variables, such as: vibration (x,y,z), contact temperature, humidity and atmospheric pressure. Available in versions with IO-Link or Modbus communication protocol.

CMSW Line differentials

- Reliable and precise

- Robust - stainless steel and IP69K version

- Monitors vibrations of up to 6kHz on all 3 axes

- Operating temperature from -20 to 80°C

- Real-time monitoring

- Monitors up to 6 variables

- Compact and easy to install

Application

CMSW sensors, when integrated with a PLC or gateway, form

a condition monitoring system for industrial machines. They

can be used temporarily or permanently in machines and

automation systems.

These sensors can be applied to turbines, pumps, gearboxes,

homogenizers, separators, alternators, mixers, packaging

machines, compressors, turbines, injection moulding machines,

machine tools, among others.

CMSWs can be applied to prevent problems such as:

- Unbalance

- Misalignment

- Looseness

- Unwanted impacts

- Gear and belt failures, among others.

Communication

These sensors are available in Modbus and IO-Link versions:

- CMSW-IOL communicates via the industrial IO-Link protocol. CMSW-IOLs are connected to an IO-Link master that can be connected to a PLC or edge gateway, allowing access to and configuration of sensor parameters.

- CMSW-MOD communicates via the Modbus industrial protocol and can be connected directly to a PLC or edge gateway, allowing access to and configuration of sensor parameters.

If the edge gateway is used, the data can be viewed by the end user via the WEGnology platform.