WEG offers efficient solutions in the mining business and has recently closed a deal to supply ten electric motors to Carbonífera Rio Deserto, a pioneer in coal mining exploration in industrial scale in Criciúma, SC, in the south of Brazil. The agreement began in October of 2007 and two machines are already in operation. Another machine is to be delivered this month still and another two until the end of this year.

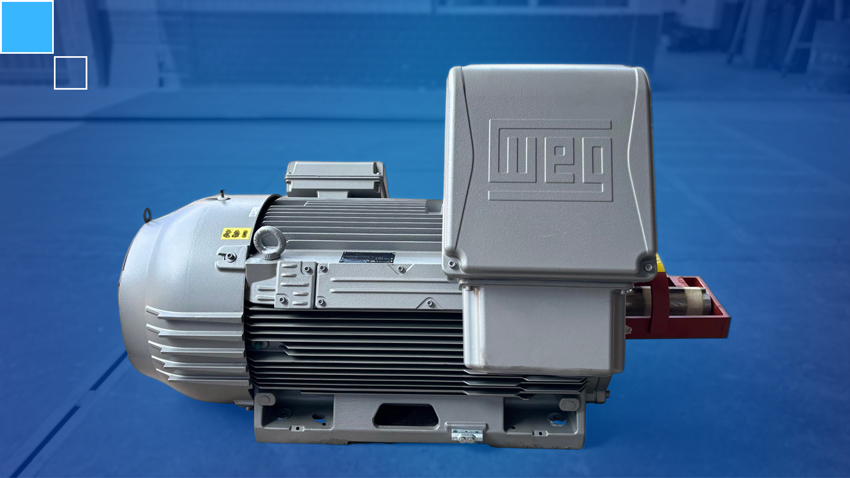

The motors, all 50hp and 6 poles, are supplied by WEG frequency inverters and used to drive the traction of mining machines. Yet, the most outstanding feature of this machine is the water cooled system. “This motor is more compact and it is possible to use the water which is released the moment the rock is cut to flow inside the electric motor”, says Rafael Nunes, Sales Manager of Novalíder, WEG’s distributor in the region. He also points out this characteristic as the most attractive to the mining companies. “It’s the only motor of the kind in Brazil”, he concludes.

Another important fact pointed out by the Technologist is that the motor doesn’t have cooled end shields. This prevents water from entering the motor due to the vibration of some parts causing the motors to burn. “The equipment supplied by WEG is completely closed, all in cast iron and dissipates heat only through the frame”, explains Nunes. “It is ideal for the mining ambient which is quite aggressive”.

Customizing mining equipment

Other good application options for the mining sector are the soft-starters and the frequency inverters, although to operate in the extreme conditions of a mine, the equipment has to be adapted. “We can’t take these products from the shelf and put them to work underground because they aren’t resistant to such aggressive conditions”, warns Nunes of Novalíder. “We disassemble the whole drive and did some adaptation so that the device may tolerate the concentration of dust and water”, he explains.

Some mines go through constant voltage variations and this made the use of soft-starters impracticable, even a utopia, according to the WEG representative. After a series of study cases, the company developed a switch to withstand these changes and obtained very positive results. “We never had problems again and today we already have between a hundred and a hundred and fifty 100hp soft-starters, or more, sold to mining companies”, estimates Nunes.

To illustrate the use of inverters, the Technologist used the case of the blowers of Carboniferas. The 600hp motor of this equipment is placed at the air outlets and operates 24 hours a day to ensure that all gases are removed and to avoid explosions. Research has proved that the blower only needs 100% power during 14 hours a day and can operate at 70% the remaining time. This control is possible with the installation of frequency inverters. “The economy in energy is so significant that the return on investment for Carboníferas came within only six months”, concludes Nunes.