Hydraulic Units

Economy and easy implantation

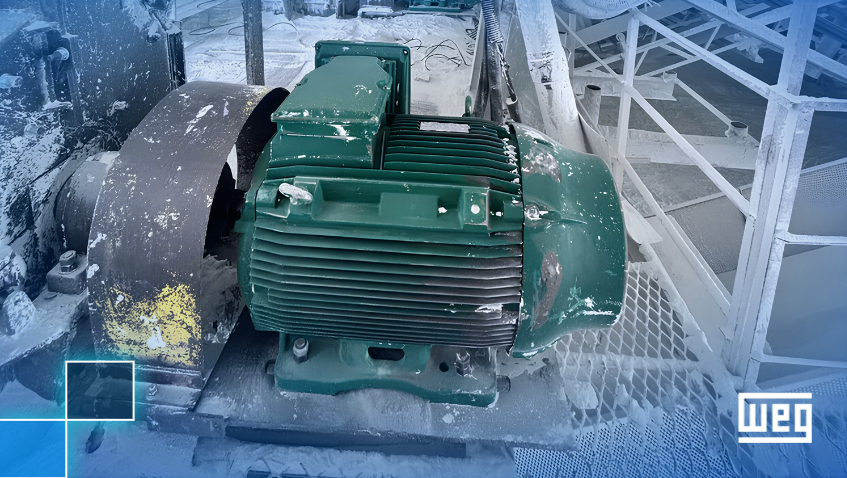

Hydraulic units include several devices, such as oil tanks, displacement pumps, directional valves, retention valves and actuators. They are arranged in logic circuits to enable the movement and control of a certain machine by means of fluid displacement, performed by one or more sets of electric motors and hydraulic pumps.

Due to their simple operation, hydraulic drives are used in many different applications, such as presses, thermoforming machines, truck dumpers, injection molding machines and calenders.

It is worth of notice that in this kind of application, when no movement is needed, both the hydraulic pump and the electric motor keep running at rated speed with the hydraulic fluid circulating, resulting in waste of electric energy and unnecessary oil heating. On the other hand, turning off the electric motor may cause damages such as the equipment burn out due to successive starts and excessive mechanical wear of the oil pump.

WEG energy-efficient solution for hydraulic units allows adjusting the motor and the pump speed according to the real need of the machine, resulting in energy savings at the moments when the set just circulates the fluid due to the process characteristics (for example, change of the part to be stamped on a press or a truck entering/leaving a truck dumper).

A great advantage of this solution is the low interference in the machine system, since there are no mechanical changes in the motors, and the machine can continue running with its original starter in case of maintenance of the drive.

Specifically for injection molding machines, the speed modulation of the electric motor is performed by means of an exclusive software application installed on the PLC of the variable speed drive, using the native analog signals sent by the hydraulic system. In a machine of this kind, WEG energy efficiency solution generates savings in virtually any operating cycle, since the requirements of the hydraulic system vary according to the cycle phase (opening and closing of the mold, injection and compression, cooling and dosing).

The proposed solution is an excellent option to retrofit an older machine, because modern injection molding machines use a similar concept; however, the investment in a new machine is much higher. It is important to notice that due to the complexity and wide configuration range of the injection molding machines available on the market, we recommend that you contact WEG in case you are interested in this solution.

Benefits

- Electric energy savings of up to 60%.

- Easy implantation with few impacts on the production system and injection molding machine.

- Lower temperature of the hydraulic fluid and consequent reduced wear of the hydraulic components.