This event is regarded as a traditional forum dedicated to discuss and exchange experience about success mining projects with focus on cost savings and increase of productivity among the 200 Largest Brazilian Mining Companies. Several innovative works were presented at the workshop where WEG highlighted the cost reduction, energy saving and maintenance issues for a mine and for a mining plant. With this subject, WEG also sponsored the 19º Excellence Award for Brazilian Mining-Metallurgic Industry. Success cases related to mineral excavation, maintenance, mining safety, and environment protection are running for the Excellence Award.

According to a report about energy issued by the brazilian Ministry of Mines and Energy, on average, 92% of the electricity is consumed by electric motors with power in a mining plant and, according to ABRAMAN (Brazilian Association for Maintenance and Asset Management ), the installed motor base in Brazil has an average age of 17 years , with obsolete electrical equipment, either deteriorated or not suitable for the application conditions.

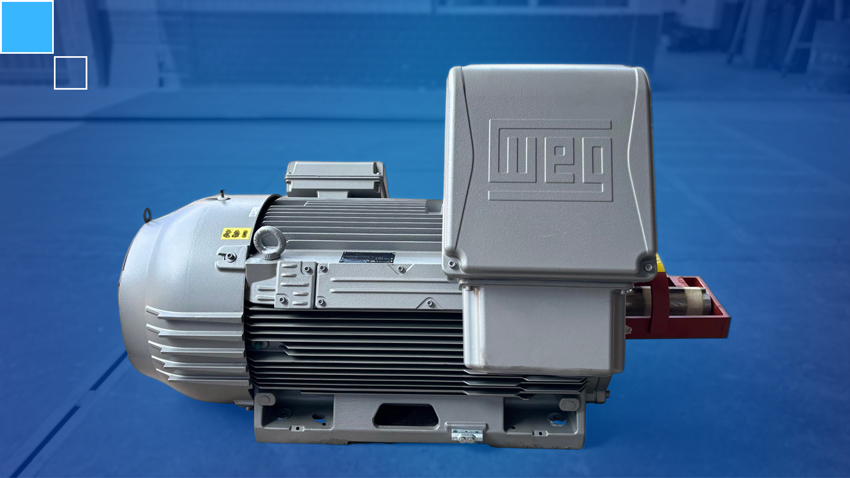

Concerning about these problems, WEG presented at the event held on 9 and 10 May in Belo Horizonte, Brazil, the lecture "Reducing costs on electrical systems: reliability, flexibility and energy efficiency", with emphasis on the most recent governmental directives about energy efficiency, replacement of current electric equipment and WEG product lines specifically designed for Mining applications, which include electrical and mechanical features that ensure high reliability and energy efficiency levels.

Learn more about WEG products for Mining application.