WEG´s expertise of manufacturing dedicated application motors allowed the company to launch a new concept of electric machines. We refer to the new WGM20 motor line that was designed to meet the most demanding efficiency levels and safety requirements in the industry. The new product platform is a result of deep R&D and technical studies carried out by WEG engineering team including a series of computer programs and state-of-the-art tools that have been used for the numerical, static, dynamic, thermal and electromagnetic analyzes leading to design optimization of each component and their mutual interaction.

To ensure the expected result, these calculating studies and analyses have been validated by prototypes that were tested and evaluated under different operating conditions, allowing great flexibility of electromagnetic designs so as to meet a wide variety of application requirements such as low starting current, high efficiency, among others.

WGM20 motors are compact machines designed in such a way to provide very low noise level, tough structural frame to ensure excellent performance at temperatures ranging between -20°C to + 50° C. The product is supplied as standard fully suitable for VFD operation.

Additional features for this machine include reduced frame design and the possibility to be installed in small rooms, which is typical for marine segment in boats and ships.

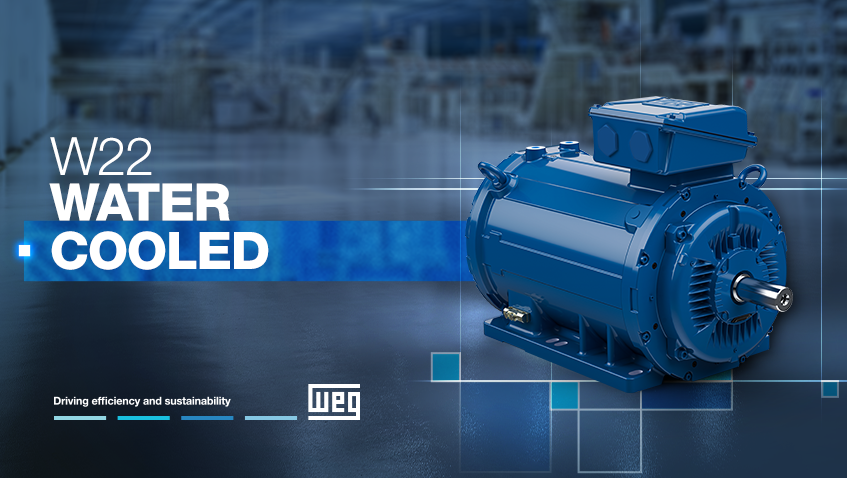

To ensure reduction of losses and maximize efficiency levels, the WGM20 motors were designed with a new cooling system that allows water and air go through the motor frame, not requiring the installation of a separate heat exchanger, which is also beneficial to offer a compact product.

This new cooling circuit also makes inspection services and the cleaning of water circulation channels easier, resulting in reduction of maintenance costs.