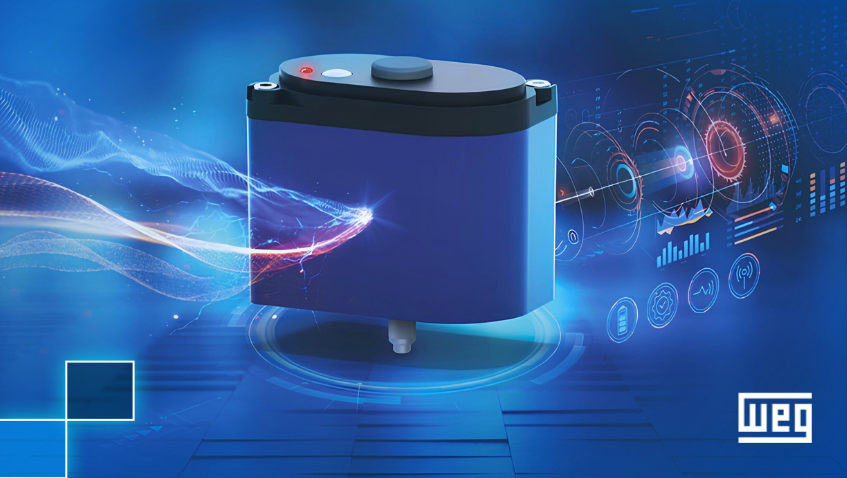

A WEG está fornecendo 12 sensores inteligentes WEGscan100 para uma importante planta de dessalinização por osmose reversa localizada em Barbados. Cada motor de 600 HP da planta receberá três sensores, responsáveis por monitorar variáveis essenciais para o desempenho das bombas utilizadas no processo, entre elas temperatura, vibração nos três eixos e campo magnético.

Os dados coletados pelos sensores são enviados para a nuvem por meio de um smartphone ou Gateway, permitindo o acompanhamento em tempo real. Integrado à plataforma WEG Motion Fleet Management (MFM), o sistema possibilita análises avançadas por técnicos e especialistas, além do uso de inteligência artificial para diagnósticos autônomos, aumentando a confiabilidade da manutenção preditiva.

O fornecimento marca a entrada da WEG com soluções de digitalização no mercado de monitoramento em Barbados, onde ainda há baixa presença desse tipo de tecnologia. Para a empresa, representa o fortalecimento da estratégia de oferecer soluções integradas, escaláveis e alinhadas à Indústria 4.0. Para o cliente, significa ganhos de produtividade, redução de custos com falhas e paradas desnecessárias, além de maior eficiência no acompanhamento de ativos críticos.

Com essa entrega, a WEG reforça sua capacidade de disponibilizar tecnologias inovadoras para a gestão de manutenção, oferecendo ao mercado internacional mais confiabilidade, eficiência e suporte às operações industriais.