Across major sites in the Middle East, thermal management and mechanical reliability are not only performance criteria. They are essential for operational continuity.

In this context, WEG and D’Hondt Thermal Solutions (DHTS) combined their expertise to equip a major energy complex with high-efficiency industrial air coolers.

A partnership built on innovation, precision, and long-term vision.

A large-scale project at the heart of the Middle East

This strategic project is part of a global framework agreement between WEG and DHTS. Its goal is to equip an oil and gas site with a complete air-cooling system designed for continuous operation under extreme climatic conditions: heat, dust, and salty air. In such environments, every component must be engineered to last.

The combination of WEG’s electrical motor technology and DHTS’s thermal engineering expertise addresses a dual requirement: energy efficiency and continuous service. Together, the two companies deliver solutions capable of ensuring thermal stability and process safety while optimizing energy consumption.

DHTS – A French expertise recognized worldwide in industrial thermal engineering

D’Hondt Thermal Solutions, a French company founded over 70 years ago, has established itself as a global leader in industrial cooling. Its air-cooler solutions, used across major international energy sites, ensure thermal regulation of critical processes in oil, gas, and petrochemicals.

With operations in France, Saudi Arabia and South Korea, DHTS designs and manufactures systems capable of continuous operation. This international presence ensures close operational proximity to key players in the energy sector and precise adaptation to local realities.

Its air-cooling technology requires neither water nor refrigerant fluids, a strategic choice in arid regions where resource efficiency is a key industrial priority.

WEG – Powering energy with reliable motor technology

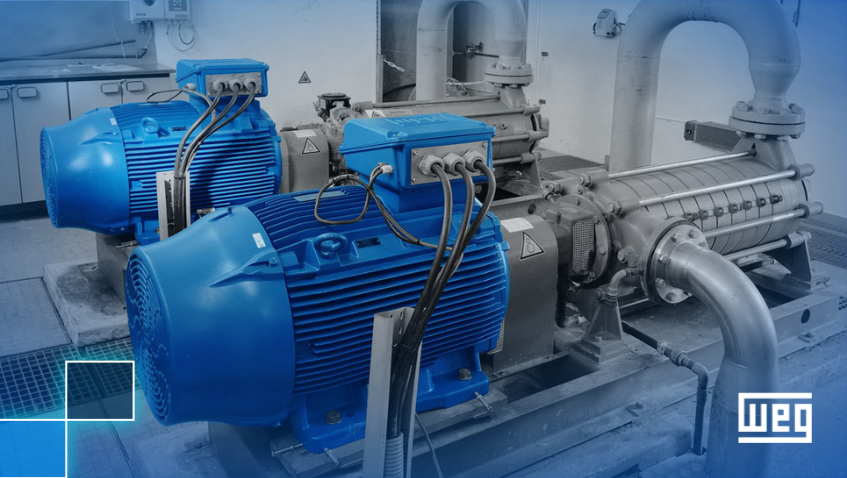

To ensure the airflow required for cooler operation, WEG supplies all the motors and variable-speed drives for the project. Deliveries began in early 2024 and will continue until the end of 2026.

The equipment includes 496 W22 motors — mainly 37- and 45-kW models, complemented by four high-power 110 kW, 12-pole units — as well as four AFW900 control panels used for system regulation.

The W22 motors are engineered for harsh environments. Their design, built on decades of industrial experience, combines mechanical robustness, high protection ratings, IE3/IE4 energy efficiency, low vibration, and ease of maintenance.

Each component, from motor to drive, is built to operate continuously with minimal human intervention. In the field, this robustness translates into fewer unplanned shutdowns, reduced electrical consumption, and improved operational stability.

A collaboration built on trust and precision

The cooperation between WEG and DHTS is rooted in a long-term relationship. Engineers from both companies work hand in hand through calculations, testing, validation, and production follow-up. This constant dialogue, from design office to commissioning, ensures consistency and reliability of the entire system.

The global framework agreement formalizes this approach: a long-lasting partnership based on technical complementarity and transparency.

DHTS, a French reference in industrial cooling, has built its expertise around a clear philosophy: simple, robust, and efficient solutions.

WEG, a global specialist in electric motorization, adds its energy-efficiency know-how and mechanical precision.

It is this rigorous approach that enables both companies to deliver equipment capable of operating 24/7, year after year, without compromising safety.