Increasingly smaller and smarter sensors have become popular and can be found integrated into mobile phones, tablets, aircraft telemetry systems, automobiles, electrical machines, among other equipment. The evolution of storage capacity, data processing, connectivity and the decrease in sensor size allowed its massive use in the most diverse domestic and industrial applications. These are devices like these that capture and transform data into user-accessible information. And this exponential volume of information directly implies the advancement of new data processing technologies in order to manage more directly and practically the information captured by the sensors, with minimal human interference.

Sensor more intelligent with Machine Learning

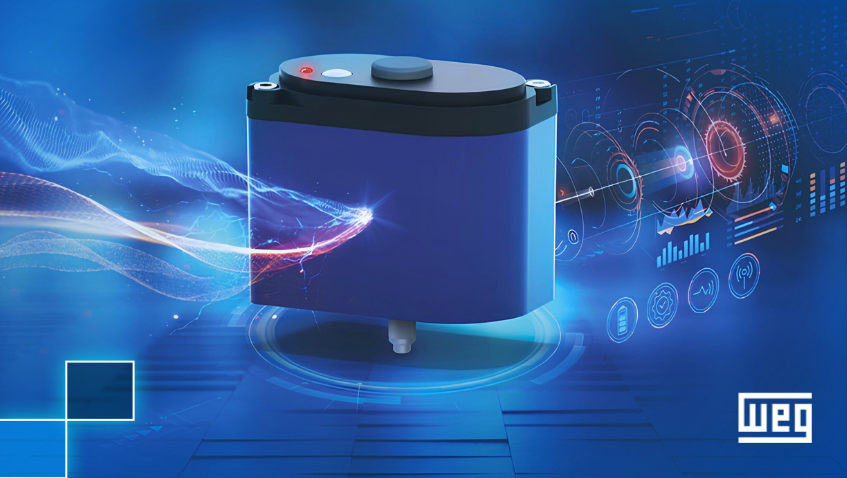

It was with this idea that WEG launched in 2018 the WEG Motor Scan®, an intelligent sensor that has been helping to diagnose the performance of various equipment. And now, with the launch of WEG Motor Specialist, module with artificial intelligence and machine learning, the sensor learns about the operating patterns and deviations that the monitored electric motor presents during its operation and makes this data available automatically through a Gateway to WEG Motion Fleet Management. And it is from this learning that the WEG Motor Scan® identifies, without human interference, vibration occurrences that alter the operating patterns of the monitored equipment. Artificial intelligence in favor of machine reliability, productivity and availability.

When developing the WEG Motor Specialist module, capable of performing the automatic diagnosis of imbalance and misalignment failures of electric motors, as well as load and consumption indicators, it was essential to prove the reliability of the solution in advance, experimenting within the testing laboratories.

How WEG experimentally validated the imbalance and misalignment

To identify these parameters, a statistical methodology based on diagnostic agreement was used, in which the WEG Motor Scan® was challenged to respond with the motor operating standard defined for two types of failure: unbalancing and misalignment, being tested also in the ideal state (balanced and aligned). The results presented by WEG Motor Scan® were compared before and after the imposition of failures, for agreement analysis. To ensure the reproducibility of the results, more than 15,000 measurements were performed in a controlled environment, within the WEG test and research laboratories, totaling 120 fault modes in several motors. The concordance index reached 92% between the failure generated and the diagnosis of WEG Motor Scan®, an excellent indicator of the reliability of automatic monitoring diagnosis.

The validation process is continuous, and allied to the internal structure of WEG, with more than 17 motor testing laboratories, performs more than 60,000 tests per year. Additionally, in 2021, WEG will have installed more than 1,000 sensors in its plants, already in operation with the WEG Motor Specialist.

With the implementation of fault diagnosis through the WEG Motor Scan®, the Department of Maintenance of the WEG plant started to rely on these sensors and integrated artificial intelligence for vibration monitoring of machines, reports the Director of Engineering of WEG, Rodrigo Fumo.

Thanks to the solution, it is possible to eliminate the verification routes and the analysis of vibration spectra to identify the main occurrences of failure, which would lead to high costs and longer time of delivery of the analysis to define the motor diagnosis. With the WEG Motor Specialist module, the fault diagnosis by unbalance and misalignment is done autonomously and assertively allowing the user a fast and cost-effective maintenance action.

WEG, recognized for acting in several industrial, commercial and residential applications, offers to the market several combinations of high-performance solutions for Industry 4.0, developed with high technology and innovation, with the aim of improving industrial processes around the world. Learn more at: www.weg.net/wegmotorscan