RETAINING ASSET VALUE of investment in existing plant and equipment is aided by WEG’s custom-made electric motor replacements which can match a wide range of outputs, voltages and speeds as well as most motor applications. WEG’s high efficiency drop-in replacement motors can be designed and manufactured to replace any standard or non-standard industrial electric motor. This custom-design capability distinguishes WEG from many of its competitors.

“This WEG flexibility allows users to replace an obsolete motor in their plants with a modern, energy efficient drop-in replacement motor. Of course, this is more cost effective for higher value, and medium and high voltage motors,” says Russell McCabe, Field Sales Manager at WEG Electric Motors UK Ltd. “Designing a new motor with better electrical performance, while maintaining the same mechanical mounting dimensions, is much less expensive than trying to modify the existing motor foundation to adapt a standard motor. The higher operating efficiency of new motors brings immediate energy savings, which could pay back the investment within a very short period of time and, over the motor life, the cost is usually much less than rewinding. Improved availability and lower maintenance costs also bring significant cost savings although they are more difficult to quantify.”

A modern motor is often capable of higher output in the same envelope and the availability of extra performance can assist in debottlenecking a process where throughput had been limited.

Other performance improvements from a replacement motor have included: lower noise levels; suitability for use with a variable speed drive; motor certified to latest ATEX hazardous area requirements.

“As a leading global supplier of motors, drives and transformers, WEG have a unique experience in designing high efficiency AC induction motors for a wide range of applications, from small machine sizes to very large. Additional custom-made special features, such as special shafts, special sealing or ventilation, special insulation requirements and others, will also allow the users to improve maintenance procedures, increase the lifetime of the electric motors and consequently decrease operational costs.

“Until now, customers with an obsolete, non-standard size motor were faced with a challenge – either modify a piece of machinery or the motor base to receive a new standard size motor or continue to rewind the existing motor, decreasing some of the important original electrical performances,” continues Russell.

“WEG capability and flexibility to design custom-made motors will enable these users to replace old motors and even upgrade electrical and mechanical performances, keeping the motors overall dimensions within the space constraints imposed by the existing installation. WEG experience for building drop in replacement motors for standard and special applications is second to none.

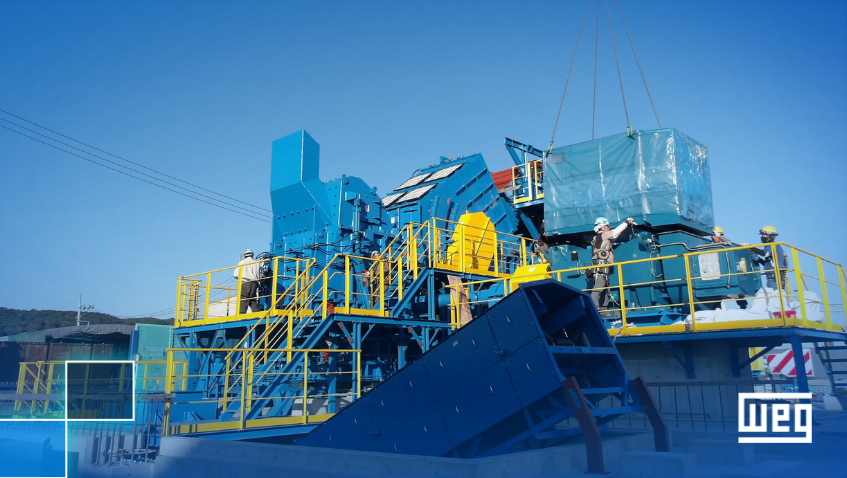

“As an example, our engineers designed and installed the world’s largest TEFC one piece cast iron induction motor at the Collahuasi Mine in northern Chile, driving conveyor belts to remove copper ore. This motor, designed and manufactured in a 630 IEC frame with 2100 kW output, had an efficiency of 97.5%. WEG’s drop-in replacement motors are committed to meeting customers’ needs for cost-effective improved efficiency and reliability.”

También puede interesarte por:

Sobre WEG

Fundada en 1961, WEG es una empresa global de equipos electro electrónicos que opera en el sector de bienes de capital, con enfoque en motores eléctricos, reductores, accionamientos y controles, generación de energía y transformadores, productos y sistemas de electrificación, automatización y digitalización. WEG se destaca en innovación al desarrollar constantemente soluciones para satisfacer las principales tendencias en eficiencia energética, energías renovables y movilidad eléctrica. Con unidades de fabricación en 15 países y presencia en más de 135 países, la empresa cuenta con más de 47,000 empleados en todo el mundo. Los ingresos netos de WEG alcanzaron los R$ 38,0 mil millones en 2024, con un 57% provenientes de mercados externos