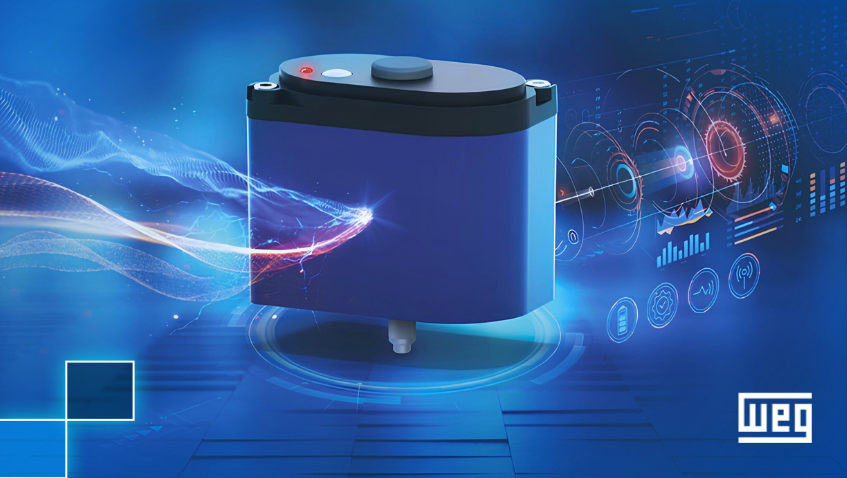

WEG has taken an important step in expanding its digital solutions with the supply of 12 WEGScan100 smart sensors for a renowned reverse osmosis desalination plant located in Barbados. This project reinforces the company’s commitment to delivering cutting-edge technology for predictive maintenance, even in third-party assets, raising the standard of operational reliability in the water pumping sector.

The sensors were applied to electric motors used in critical pumps of the desalination process. Each motor received three sensors, ensuring full coverage of the most relevant variables for asset integrity, such as temperature, three-axis vibration, and magnetic field.

The supply was the result of a connection established during the international WEFTEC 2023 trade fair, where WEG’s sales team identified the customer’s need for remote monitoring solutions. From that contact, a precise proposal was developed, with the delivery of the sensors currently underway and shipping directly to the Caribbean country.

Although this is a new customer and the motors are not from the WEG brand, the plant chose WEG technology due to the robustness, versatility, and integrated intelligence of the WEGScan system. Through the WEG Motion Fleet Management platform, the data collected by the sensors is analyzed with the support of artificial intelligence, enabling autonomous diagnostics and early failure alerts.

In addition to simple installation and communication via Bluetooth or Gateway, the differential lies in the WEGsense and WEGsync technologies, which enable synchronized diagnostics and detailed structural analysis, even in challenging environments.

With this supply, WEG expands its presence in the Caribbean and reinforces its positioning as a provider of complete solutions for Industry 4.0 and smart maintenance, regardless of the origin of the monitored equipment.