Honda’s plant in Manaus, Brazil, one of the company’s largest industrial units outside Japan, operates three daily shifts to meet the high demand for motorcycle and component production. In a continuous pursuit of reliability and productivity, the company adopted WEG’s asset condition monitoring solution, consisting of WEGscan100 smart sensors and the WEG Motion Fleet Management (MFM) software.

The system enables continuous and remote monitoring of critical parameters such as vibration, temperature, and operating hours, sending the collected data directly to the cloud via a gateway. The information is made available in comprehensive reports, allowing maintenance teams to anticipate failures, plan interventions at the right time, and reduce operational risks.

The practical benefits of this implementation were proven in real situations, where predictive monitoring prevented critical failures, reduced maintenance costs, and increased equipment availability. Through the continuous collection of vibration, speed, and temperature data, it was possible to implement a predictive approach with more accurate and timely technical interventions.

“The WEGscan100 condition monitoring solution significantly increased the efficiency of the maintenance team. The technology allowed labor to be used more effectively in corrective actions, expanded predictive maintenance, and reduced total maintenance costs. “We avoided premature equipment failures, increased asset reliability and availability through real-time monitoring, and reduced team exposure to risks — for example, the team no longer needs to climb operating equipment to perform inspections. Interventions are now scheduled only when truly necessary, reducing repair time and costs,” highlights Eduardo Sodré, head of the electrical area at Honda Manaus.

Honda’s experience shows how the integration between WEGscan100 sensors and the WEG Motion Fleet Management platform is transforming industrial maintenance. With reliable, real-time data, the plant achieves greater safety, efficiency, and predictability, ensuring continuous operations in a high-demand production environment.

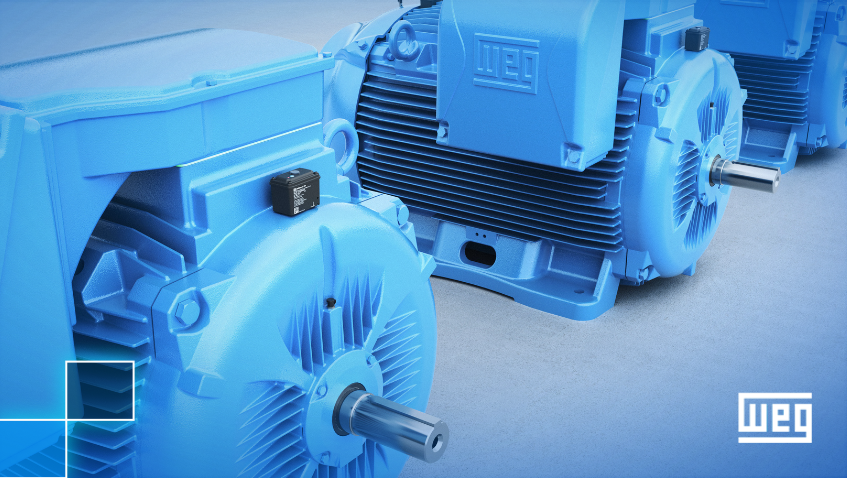

Achieve results like these with WEGscan100 sensors for rotating assets. Visit the page and complete the form to speak with our specialists.