Por meio do direcionamento estratégico da companhia para seu modelo de negócio, a WEG possui em todas as suas unidades de negócio soluções e produtos mais eficientes e com menor impacto ambiental, como energias renováveis (solar, eólica), mobilidade elétrica, eficiência energética, dentre outras. A WEG desenvolve produtos considerando rigorosos critérios de risco relacionados à saúde e segurança. Na fase de desenvolvimento, são aplicadas análises como por exemplo: Quality Function Deployment (QFD) e Risk Assessment.

Sistema de Gestão da Qualidade

A WEG aplica um sistema de gestão da qualidade certificado, baseado em requisitos externos e nos requisitos dos nossos clientes.

A seguir são apresentados alguns destaques considerando a variedade de produtos e soluções que a empresa fornece ao mercado por meio de suas diferentes unidades de negócios.

Eficiência energética e Industrial

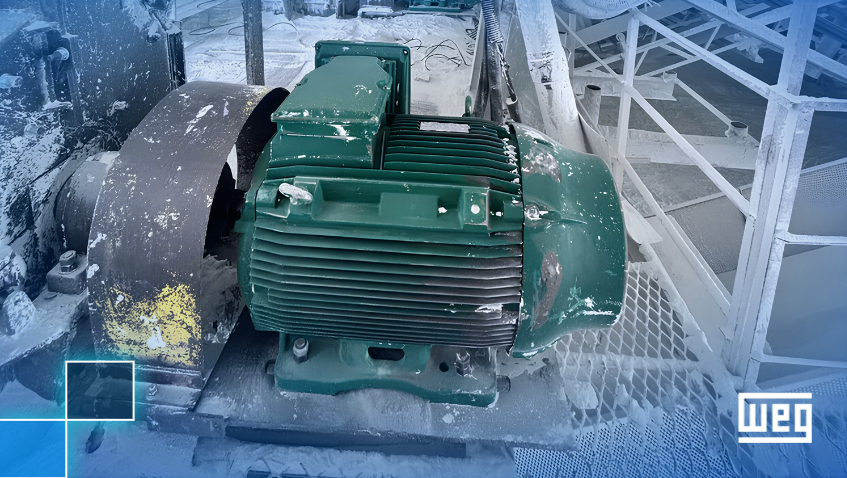

Motor W51 HD (High Density)

Solução eficiente e compacta, que entrega performance superior com tamanho e peso reduzidos em relação à linha antecessora (até 25% maior densidade de potência – kW/kg), bem como aos seus concorrentes no mercado. Promove assim o uso racional de matérias-primas na fabricação dos motores, bem como dos potenciais efeitos de sua transformação, apresentando redução de aproximadamente 15% na emissão de GEE em relação à linha anterior.

VSD for Motors

High-tech VSD for driving and controlling three-phase induction and permanent magnet motors. Thanks to its technology, this VSD model provides energy savings, safety, increased productivity and quality in the process network in which it is implemented. The CFW900, together with permanent magnet motors, offers the highest energy efficiency solution on the market. The new HMI with Bluetooth® connectivity is ideal for panel builders and repair shops, enabling programming, monitoring, parameter backup and other functionalities via tablets or smartphones.

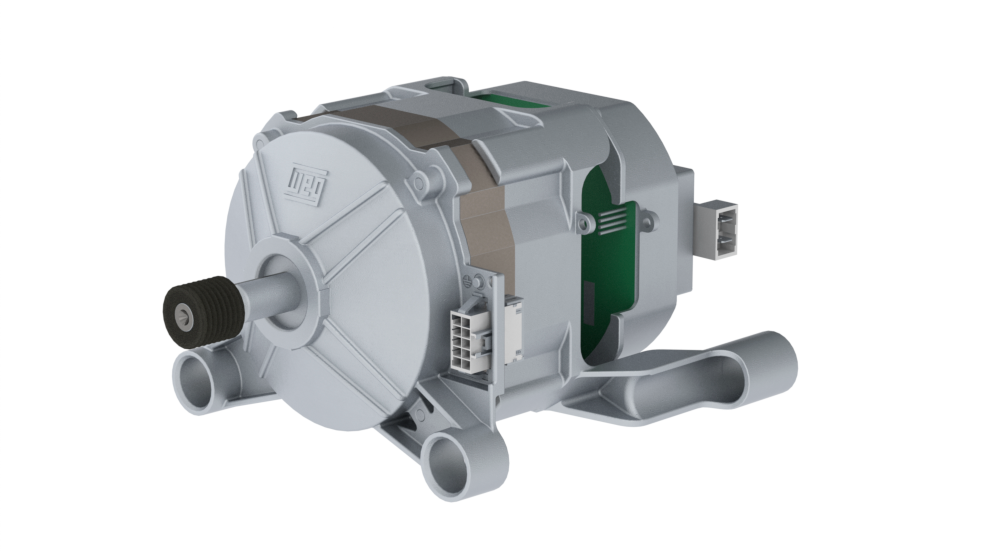

BLDC Motor Line (Brushless DC)

For application in front load washing machines, it delivers a 60% improvement in the performance of the operating cycle and, consequently, a reduction of GHG emissions during the operation phase. This line currently represents 20% of the volume sold by WEG for front load washing machines.

Renewable Energy

Wind Power

In July 2022, WEG announced the release of a new wind turbine platform with 7 MW power and 172 meters of blade rotor diameter. This wind turbine will become the largest machine in operation in the Brazilian market. More powerful and efficient, the new model brings greater generation to wind projects.

Solar Power

WEG established itself as one of the main suppliers of products and solutions for solar plants in Brazil, bringing efficiency that drives sustainability in cities, industries, agribusiness and homes across the country. WEG has a vast portfolio of products for all the stages of photovoltaic solar generation projects, with solutions for the energy conversion and internal distribution system, from the plant to the point of connection to the electrical system through high voltage substations.

Hydroelectric Generation

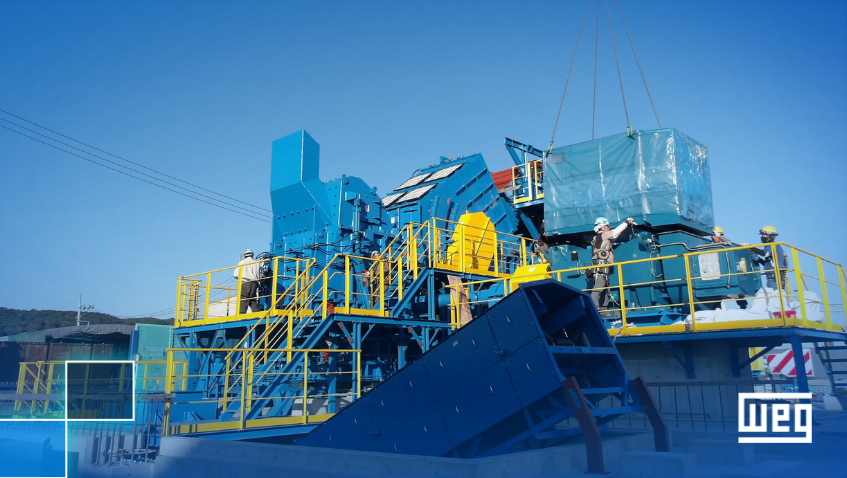

WEG was selected to supply the generators for São Roque Hydroelectric Power Plant, located in the city of Vargem-SC. The generators are one of the most important parts of the enterprise for São Roque Hydroelectric Power Plant. With 285 tons each and approximately eight meters in diameter, this equipment is among the largest electric hydrogenerators ever produced by WEG.

São Roque Hydroelectric Power Plant has an installed capacity of 142 MW, which, on average, is enough to supply a city with approximately 170,000 inhabitants. The generators started commercial operation in July 2022.

Commercial and Industrial Energy Storage

Energy storage systems are used in commercial or industrial facilities, being the complete solution for storage and management of electrical energy. They can be configured to perform various functions in smart systems for generation, transmission and distribution of electric energy. The system is composed of an energy control and management solution, and it is mainly recommended for applications in systems installed behind the meter in industries, stores, shopping malls, residential condominiums and electric mobility infrastructure.

Transformers for Renewable Energy

The reliability of the transformers developed for solar plants aims at guaranteeing the supply of energy, allowing access to electricity through renewable energy generation sources. In the line of transformers for wind farms, WEG developed an extremely compact electrical and mechanical transformer design. Additionally, due to the installation layout, in which the source and the transforming unit are very close to each other, the system produces smaller losses and greater energy efficiency.

Electrical Mobility

Integrated solutions for electric vehicles

WEG continually develops innovative technologies to create electric traction systems, as well as all the electrical infrastructure necessary for the operation of electric vehicles. WEG electric traction systems can drive various road, rail and navigation vehicles, such as urban trucks and buses, vans, forklifts, trains, monorails, support vessels and tugboats.

Digital Solutions

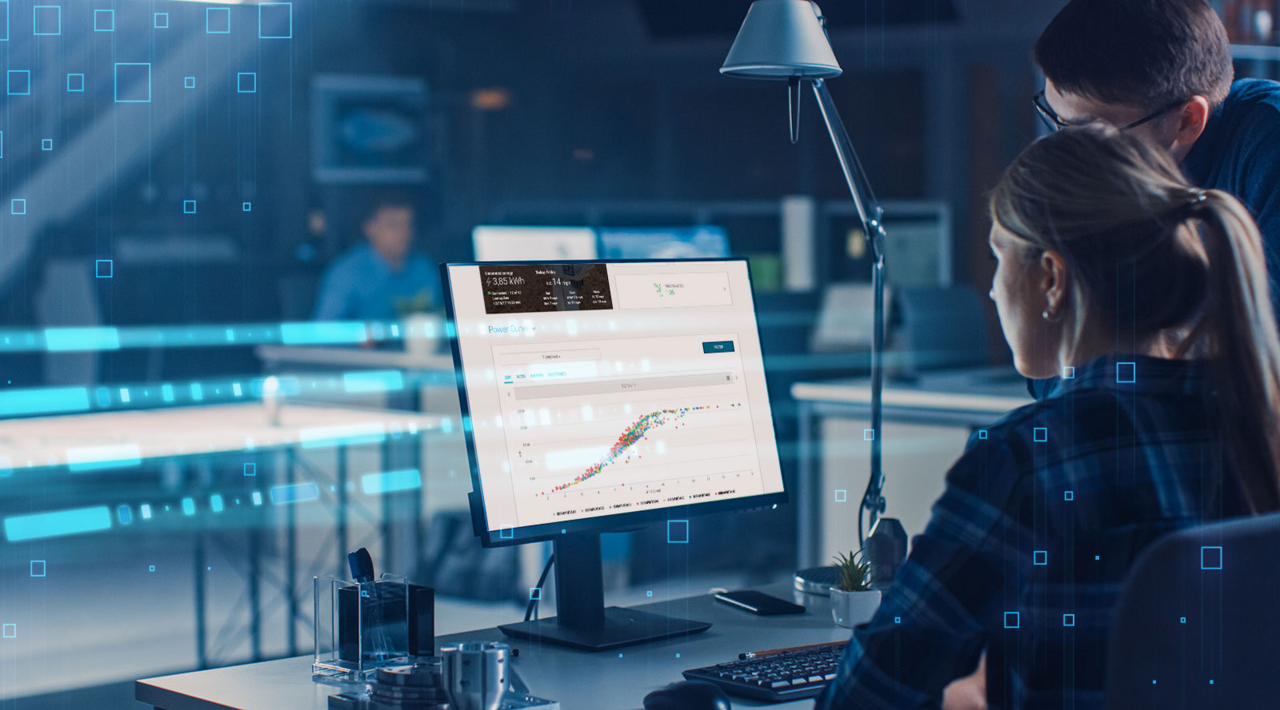

Smart and sustainable systems

Smart systems are able to integrate different devices and machines, as well as installations and processes, promoting efficiency in decision-making and increasing operational efficiency. Smarter solutions and systems also promote more efficient use of energy resources helping reduce the carbon footprint of operations at all levels.

Automation Systems

WEG supplies completely integrated control systems that guarantee high performance of industrial processes, easy operation and productivity gains by means of state-of-the-art technology. The success of the integration of this system is in the synergy of WEG products, where motors, drives, generators, electric panels and software applications are integrated, providing the ideal solution for each requirement. The control of industrial processes requires automation systems with high reliability and uptime levels, in addition to easy asset management by the maintenance teams, extending the equipment service life and streamlining the use of resources.

WEG Transformer Fleet Management and WEG Power Transformer Specialist

WEG Transformer Fleet Management is the ideal solution to monitor online and manage the fleet of oil or dry-type transformers, enabling customers to maximize the efficiency of their operations, supporting the streamlined management of industrial plants, renewable energy generation and infrastructure. WEG Power Transformer Specialist is a digital solution used to monitor and manage power transformers that, integrated with the WEG Transformer Fleet Management platform, centralizes the signals from several sensors installed on the equipment.

WEG Motion Fleet Management

Developed to simplify and speed up the operation, maintenance and management of industrial plants, WEG Motor Fleet Management is the ideal solution for monitoring and increasing the uptime of the industrial drive fleet. Based on cloud computing technology, the performance of assets can be monitored at any time, from any part of the world. WEG Motor Fleet Management allows checking the operating status of low and medium voltage motors and drives (VSDs and soft-starters), gearboxes, gearmotors, compressors and other assets installed in any kind of industry or facility.

Ultra Low Bake (ULB) Technology for Coatings

The Ultra Low Bake (ULB) technology consists of reducing the curing time or curing temperature of powder coatings. Linked to this reduction in time or temperature (which can reach up to 35%) is the reduction in the amount of gas used in the curing ovens of customers and partners, lowering GHG emissions.

WEG partners who employ such technology in their production line, in addition to reducing environmental impact, have a significant increase in productivity and competitiveness. WEG has forty products developed for this purpose.

Eficiência material e avaliação ambiental do produto

A WEG adota, em sua cadeia de valor, iniciativas que estão alinhadas aos princípios da economia circular, através de práticas como reinserção de resíduos dos processos como matérias-primas, como por exemplo sucatas de aço da estamparia para fabricação de peças fundidas, adoção de programas de recuperação de materiais no fim do ciclo de vida de produtos através da logística reversa e planos de troca.

A aplicação desses conceitos e práticas permitiram à WEG atingir um índice de eficiência material próximo de 85%. A WEG também está em constante melhoria e evolução da eficiência energética de seus produtos e de soluções de retrofit para a extensão da vida útil de algumas linhas de produtos. Equipes qualificadas atuam tanto nos processos de desenvolvimento de novos produtos e na concepção de novas linhas quanto na implantação de processos industriais mais eficientes.

A WEG aplica a ACV (Análise de Ciclo de Vida), gerando os EPDs (Environmental Product Declarations) conforme as demandas dos clientes, pretendendo, nos próximos anos, ampliar a aplicação dessas ferramentas.