Grain Storage Silo

Quality and economy in storage

Designed to store and keep the grain quality, the Storage Silo is one of the most important applications in the agribusiness. WEG is the pioneer in the development of a specific energy-efficient solution for this segment, ensuring a better silo and grain storage management.

Once the grains reach the plant and are stored in the silo, their quality starts declining proportionally to the storage time and conditions. In order to keep the initial quality of the grain, it is necessary to aerate the product. In such applications, the ventilation often exceeds the real needs or becomes harmful by introducing undesirable moisture.

Based on that, to supply just the necessary ventilation to keep the grain quality, WEG created a high-efficiency solution consisting of:

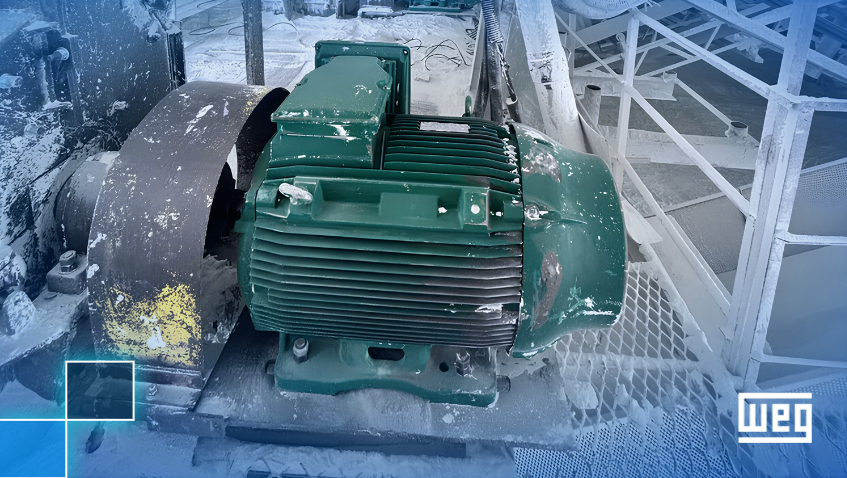

- Electric motor W22 IE3 Premium or W22 IE4 Super Premium, and CFW11 or CFW700 variable speed drive

- Electric motor W22 Magnet IE4 Super Premium or W22 Magnet IE5 Ultra Premium, and CFW11 variable speed drive

This solution allows the system to adjust to any kind of grain, providing the correct aeration rate for each product, maintaining the temperature homogeneous across the mass and producing great energy economy.

Benefits

- Energy savings of up to 90%.

- Grain mass humidity control, avoiding losses due to drying beyond the necessary.

- Temperature variation causes fewer grain breaks, producing better quality grain.

- Precise control of the stored volume.

Thermometry is decisive in this process to enable significant reduction of the fan speed and maintenance of grain quality. Likewise, in any point of the grain mass where a higher aeration rate is necessary, the system automatically adjusts to meet such demand.