Cooling Tower

Electric energy and water savings

Cooling towers are commonly used in the industry to supply cooled water for different industrial processes. The variation in their operating conditions enables the system automation, quite accessible to any application and with great reduction of operating costs.

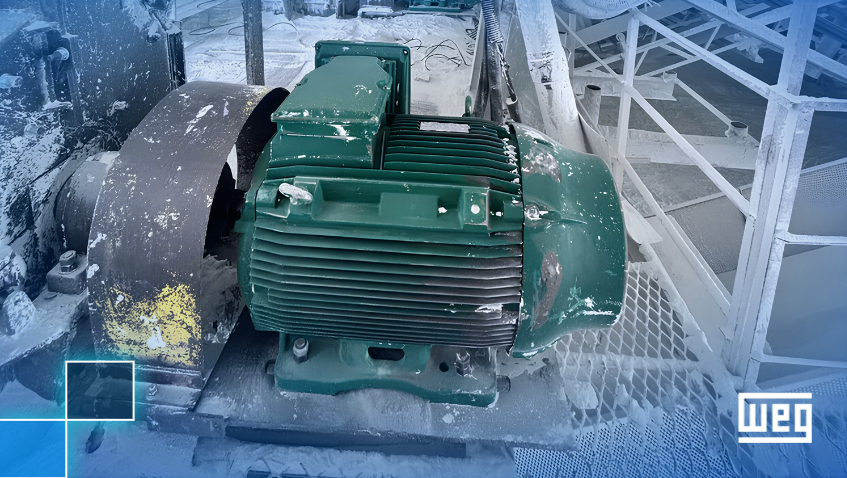

The solution consists of a high-efficiency set: W22 IE3 Premium or W22 IE4 Super Premium motor and CFW701 HVAC variable speed drive, which, when properly sized, provide a reduction of up to 80% of electric energy consumption and average savings of 22% in water per year. The solution also offers an exclusive WEG software which replaces temperature controllers and PLCs, with direct control by means of the variable speed drive.

The solution automatizes the system, varying the speed of the tower fans according to the process requirements and ambient temperature. Variable production or seasonability of local ambient temperature demand different cooling capacities automatically adjusted by the solution.

Furthermore, the speed variation control may reduce water evaporation and consequently cut down water consumption.

Benefits

- Electric energy savings of up to 80%.

- Easy implantation.

- Applicable to any cooling tower model that uses fans.

- 22% of average water savings a year.