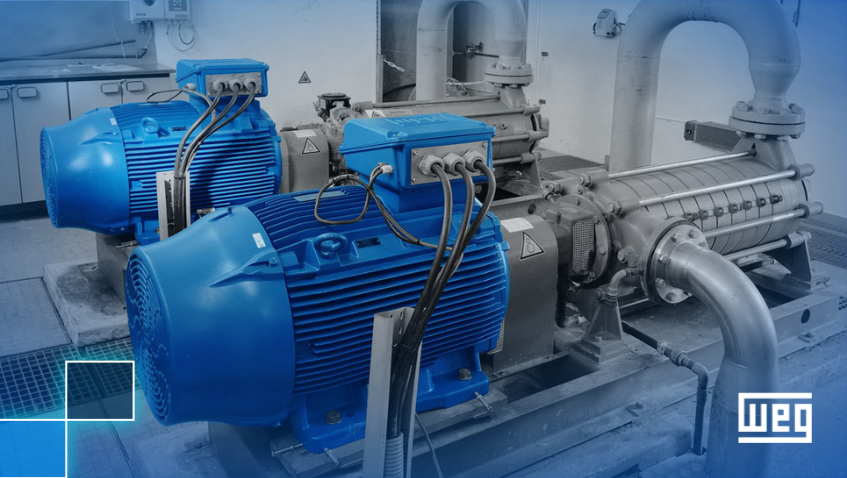

The traditional manufacturer of electric motors to the global markets WEG has complemented the already existing W60 motor line, which was designed for industrial applications such as compressors, pumps, and fans. The new design will ensure high performance and reliability even under the most severe operating conditions.

Available in three different refrigeration configurations, open, self-ventilated (IC01, WP-II); enclosed, air-air cooled (IC611, TEAAC) or air-water cooled (IC81W, TEWAC), this product line features compact design, lightweight components, reduced dimensions and footprint which saves valuable space on the skid or base where it is installed. This W60 is the most compact modular motor offered in the market.

To ensure long-lasting operation, the new W60 was designed using the most advanced software, which has resulted in a solid structure that allows operation in the most severe environments, as well as being suitable for high impact and high speed applications.

Ball bearings are standard up to 560 frame even on 2 pole motors. Its compact design allows utilization of antifriction ball bearings, grease lubricated, where other motors cannot. Sleeve bearings are standard for larger 2 and 4 pole motors and are available when required for the entire range.

In terms of electronic setting up, the W60 is easily adaptable to any medium voltage Variable Frequency Drive available in the market. The product is also suitable to operate with no speed limitation up to rated speed by standard design. An optimized insulation is available when combined with WEG medium voltage variable frequency drive.

Standard features are as follows:

• Rated output: 500 up to 16,000 kW (700 up to 21,500 HP)

• Number of poles: 2 up to 12

• Frame sizes: IEC 450 up to 1000 (NEMA 70 up to 160)

• Voltage: 2300 up to 13,800 V

• Frequency: 50 or 60 Hz

• Cooling methods: IC01, IC611 and IC81W (WP-II, TEAAC and TEWAC)

• Degree of Protection: IP24W up to IP55

• Mounting configuration: horizontal

• Bearing type: Ball or sleeve bearings

• Starting: DOL or VFD

• RTD Pt-100, two per phase

• RTD Pt-100, one per bearing

• Space heaters

• Copper bar rotor

• Global VPI insulation system

• Area Classification: Safe or Hazardous (Ex-n, Ex-t, Class I Div. 2, Class II Div. 2)

More information about this product are available at www.weg.net