The EBC500 module is an electronic device for the excitation and control of the brakes elements with the ability to communicate and synchronize with the ADL550 series drives.

The EBC500 module simplifies the brake control system by eliminating rectifiers and contactors while maintaining the highest level of safety and improving the efficiency and overall maintenance of the brake system.

The EBC500 manages the uncontrolled car movements requirements according to EN 81-20/50 and new revamping requirements UNI 10411-1.

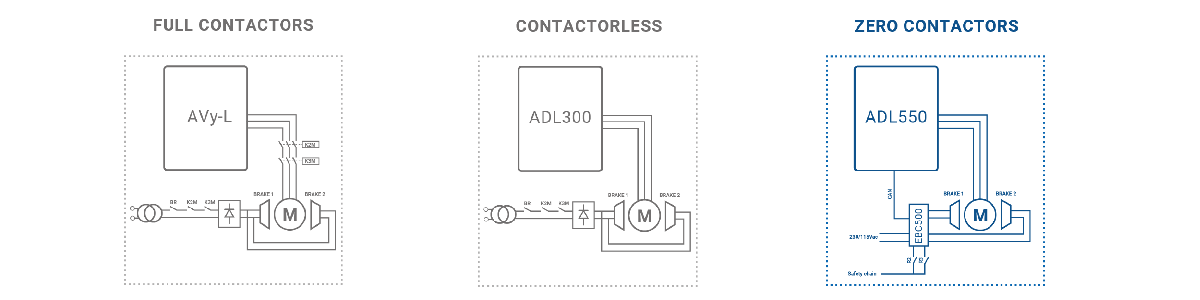

WEG has marked important milestones in its history in the elevator market. WEG has indeed been a pioneer in this industry, continuing to invest in innovation, especially in terms of safety, and introducing significant innovations over the years, from phase contactorless to the current brake contactorless technology. The combination of these aspects has led WEG to become a leader and trendsetter, always with the aim of simplifying elevator control panels while enhancing technology and safety levels for both installers and users.

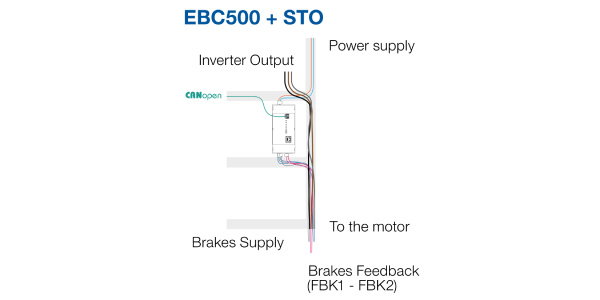

Transitioning from the traditional approach (full contactors) to the innovative solution offered by the combination of the ADL550 with STO SIL3 and the EBC500 with SBC SIL3 brings clear advantages, as illustrated in the image below. On the left, the traditional approach requires more components and extensive cabling, resulting in higher cabinet complexity for installation and maintenance. In contrast, on the right, the EBC500+STO simplifies the cabinet design, reduces its size, and lowers maintenance requirements over time. Additionally, the EBC500 electronics enhance brake control, testing, and monitoring, proactively anticipating regulatory advancements aimed at increasing overall elevator safety

COMMISSIONING

ENERGY SAVING

MAINTENANCE

TROUBLESHOOTING

SAFETY

COST SAVING

NOISE REDUCTION