WEG announced that it has successfully tested its new solution of low speed synchronous motors driven by frequency inverters for mills with dual pinions, at its testing facility in Brazil. Due to the complexity and costs, this equipment is usually tested individually. However for this important shipment, the whole unit was tested together, ensuring the reliability required in the customers application.

During testing, the equipment was run at full load and provided 250,000 Nm at the motor shaft, recording the highest testing capacity ever performed by an electrical equipment manufacturer in the Southern Hemisphere. The products tested are part of an important order from a large mining company for units that will drive 18 ball and SAG mills, both with single and dual pinion.

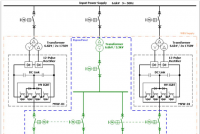

The WEG laboratory is one of the largest and most sophisticated facilities of its kind devoted for the testing of electrical equipment and systems. The tests were carried out during four weeks and included two synchronous motors of 4,700 kW, 30 poles, connected back-to-back (directly coupled to the shaft) and driven by WEG medium voltage model MVW01 frequency inverter rated at 1178 Amperes and 3,300 Volts.

Adding to the years of WEG experience in the field of motors and drives, the Electric Machinery Company of Minneapolis, USA has been added to the mining group adding over 120 years of history and knowledge in the field of synchronous motors for heavy industry.

Along with synchronous motors, WEG offers the mining industry induction and wound-rotor motors driven by frequency inverters or rheostats.

For more information on any of the mining products or WEG’s testing ability, please contact your local WEG distributor or go to www.weg.net.